|

The background to the S625 valve of 1927 was the development by the Marconi Company of long-distance short-wave beam communication. The receivers for this required two or more stages of tuned RF amplification but existing triode RF amplifiers could not provide enough gain at these frequencies without becoming unstable. The need for a screen-grid valve receiver became urgent and Captain H J Round was given the task of developing one. See also S625

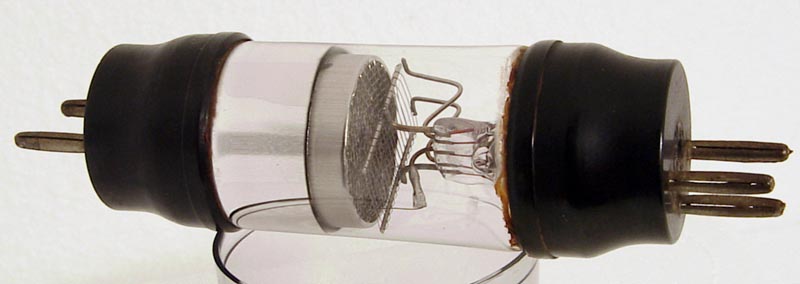

A successful screen-grid valve requires generous emission and a reasonably high gm if it is to give worthwhile amplification at the HF frequencies of interest. Small receiving bright emitters simply did not have either the emission or the gm to make an efficient screen grid valve practical. Round would have preferred to design his famous valve with an oxide coated filament but MOV had no suitable process in place at the time. It is difficult to see how the azide process (then in its early days and not always satisfactory) could have been applied successfully to the electrode structure of the Type S625. As a result, the World's first HF screen-grid tetrode had to be made using a thoriated Tungsten filament.

Captain Round designed a series of experimental samples which were made for him in MOV's Research Department. For convenience, the filament and grid assembly was 'borrowed' from that of type DE5, then in production. This assembly was mounted side-on and the various experimental samples (of which at least one still exists) differed in respect of screen grid dimensions and spacing. Having decided which of the samples best suited his needs, Round ordered a pre-production batch and got on with designing a receiver around them. Both were immediately successful. At least one complete receiver and many S625s survive in working order. Type S625 was still listed for replacement purposes at the outbreak of WWII.

Having been dropped a gift, MOV immediately set about manufacturing the new wonder valve in quantity and marketing it for domestic radio applications. This was not what it was designed for. Like most of Round's valve designs it was directed a particular specialist application (in which it was highly successful) but it was not well matched to the needs of the domestic market. It was also fairly costly to make. Once the novelty had worn off and MOVs competitors had designed their own (upright) versions, (cheaper and with characteristics more suited to domestic receivers at broadcasting wavelengths) the S625 reverted to being what it was: a specialist valve for professional short-wave receivers.

The Cossor company made an oxide-filament look-alike (Type SG210) some time during the later 1920s. It was not quite the same length and had a 2V filament rating, so it was not interchangeable with the S625. It seems to have been unsuccessful and samples are now very rare. During the later 1930s the Cossor company made a more successful oxide-filament replacement for the S625. This redesigned version had an upright electrode assembly 'borrowed' from their current SG designs for the domestic market. All samples seen are marked ARS6, which was the British Services designation for the S625.

Before leaving the S625 it is interesting to note that it is among those types in which the well-known 'tetrode kink' in the characteristic actually swings negative. This means that under certain running conditions (low anode voltage) the anode current demand (or supply?) actually reverses ie. so as to replenish the HT battery! Another consequence of the kinked characteristic was the possibility of powerful HF self-oscillation in Dynatron mode. Round, of course, knew all about this, and why, and how to prevent it, but domestic radio designers had to find out the hard way.

References: 1004 & 1005

|