|

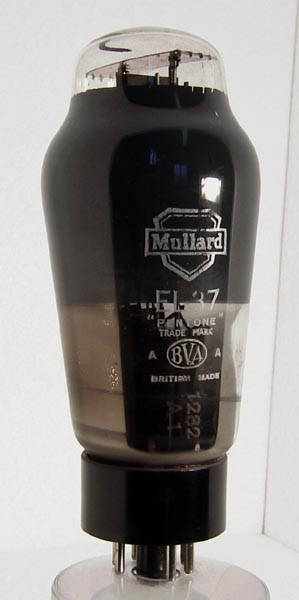

Before the introduction of the EL34 with its pressed glass foot construction and IO base. Mullard's flagship 25 Watt anode dissipation audio output pentode was the EL37.

In addition to being used on its own as the final stage of an audio power amplifier it was also employed as a driver for high power amplifiers for modulation of small broadcast transmitters. A typical 1 kW amplifier would employ a pair of triodes in the final stage.

The EL37 is not a valve that gets destroyed as used examples find their way into collections. However, we have a pair of EL37's one of which was broken in transit in 1969 on the way back to England from the Far East.

Under careful safety conditions the rest of the envelope was removed so that the construction could be investigated.

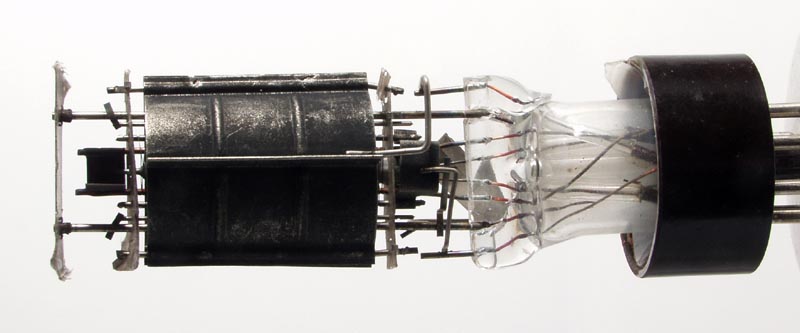

The outer construction of the electrode assembly has mica supports that hold the electrodes within the top of the classic envelope. The lower end of the electrode assembly has the support rods held in the glass pinch. The stem of the tube from which the pinch is formed is sealed to the bottom of the outer envelope and is concealed by the base.

It is at the pinch that the connections pass through the glass to the outside world. Each lead has a complex construction. The stout support is attached to a short length of metal chosen to have an expansion rate that matches the glass of the pinch. In this way the changes in temperature that occur during operation do not set-up stresses that would eventually fracture the glass and consequently the vacuum seal. This red platinum is expensive and so only a short length is used. At the base of the pinch the lead changes to a thin wire for connection to the IO base. These leads were produced as a preformed component and not built-up during the final assembly.

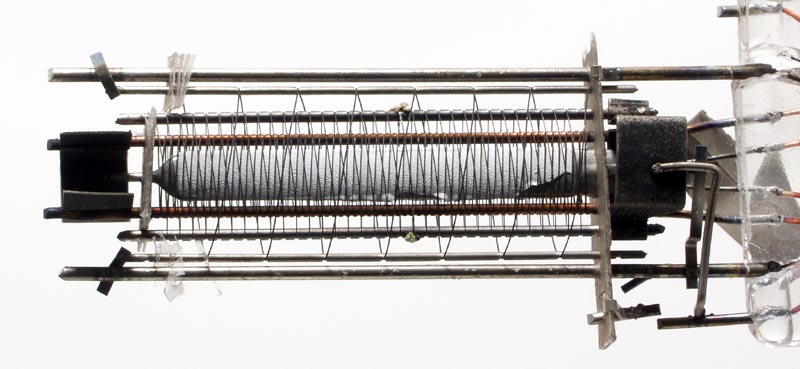

The anode is formed from flat sheet and two folded halves are held together to form an oval cavity. For additional strength the pressing introduces a corrugation. The anode material is probably nickel. This has the property of a high working temperature without softening or high emission of secondary electrons. The length of the anode is 34 mm. The oval cavity is 23 x 14 mm.

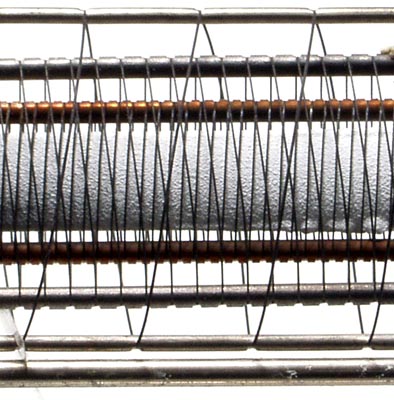

Clipping the anode support rods and removing the top mica allows the inner electrodes to be revealed. The EL37 is revealed as a true pentode with three wire grids. The grids are all wound on support rods and have an oval shape to match the anode cavity.

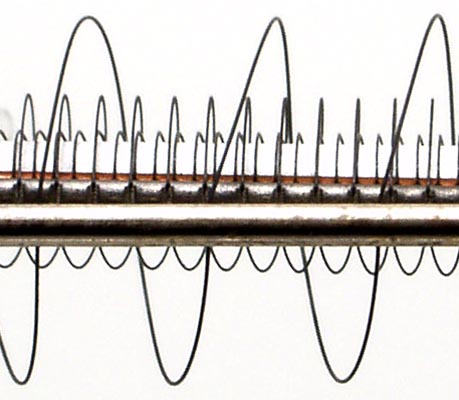

The suppressor grid, closest to the anode, is made of a fine wire that is formed into a three turn open helix, and a pitch of 5 mm. The nickel support rods are 16 mm apart and the shord dimension of the winding is 10 mm.

The screen grid has a much finer pitch of 1 mm. The nickel support rods are 10 mm apart. The short axis of the grid is 5 mm.

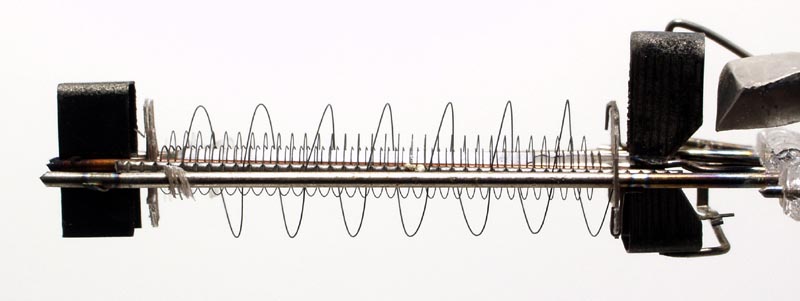

The control grid is supported on heat conducting copper rods set 6 mm apart. The grid wire pitch is 0.5 mm and the short axis is 2.5 mm. The clearance of the control grid from the cathode appears to be 0.25 mm. At the top and bottom of the support rods ia a black U shaped heat radiator.The distance between cathode and control grid needs to be small for a good gm and the EL37 has a superb mutual conductance figure of 11 mA/V.

The cathode is an oxide coated oval tube and is of a generous size. Years of being exposed to the air has resulted in some of the coating becoming detached. The large cathode area assures an adequate supply of electrons for the peak currents. Within music, the transients can be many times the average value and the peak power handling capacity of the amplifier has to reflect this and not introduce distortion by clipping the peaks.

|