|

This article, based on a paper read before The World Radio Convention, organised in Sydney by the Australian Institution of Radio Engineers, gives an excellent summary of modern practice in commercial, professional and amateur disc recording.

Methods and Processes in the Production of Pressed and Direct Recordings

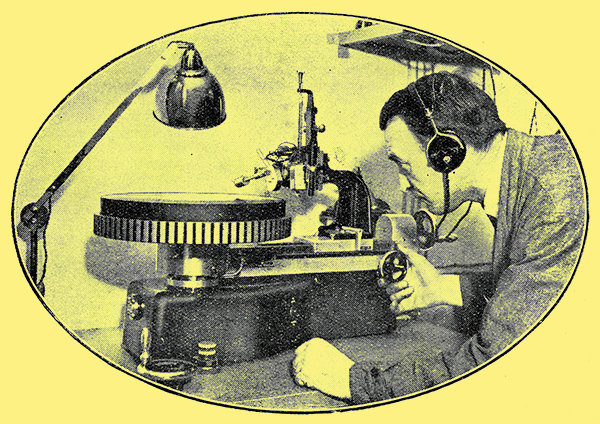

The recording machine used by manufacturers of pressed records is in reality an exceptionally high-grade precision lathe fitted with a horizontal face plate or turntable. On the turntable a soft wax disc is placed and rotated under the cutting stylus, which moves across the face of the disc on a worm drive. By several means it is possible to control the number of grooves that are cut to the inch, the average number being 90. Most of the well-known gramophone companies build their own recording apparatus, and are most secretive concerning the details of its construction. The turntable is generally driven by a gravity motor, as fluctuations in angular velocity must be reduced to a minimum, and the gravity motor provides a simple, reliable and steady source of energy.

In certain types of equipment synchronous motors are employed, and in this case it is desirable that the motor be not located in the same framework that carries the turntable and cutting head. By a suitable distribution of the motor the shaft connecting motor and turntable may be broken up with a mechanical filter, thus preventing motor vibration reaching the delicate driving head and its associated stylus.

A modern recording system (in which are included microphones, amplifiers and cutting head) is designed faithfully to record all frequencies above 250 Hz. In actual practice the equipment is designed to accentuate the frequencies approaching the upper limit as this arrangement improves the quality of reproduction and substantially compensates for needle wear. Below 250 Hz the response falls oft rapidly.

The greatest care must be taken in the manufacture of the wax and not less than 20 major conditions must be covered. Perhaps the most important requirements are as follows:-

- It must be soft enough for the stylus to cut smoothly and cleanly without friction of the magnitude that will cause the stylus to chatter.

- It must be homogeneous and of even density.

- lt must be unaffected by acid, metallic salts, or electrolysis.

Composition of Wax Masters

The greatest secrecy is maintained in the actual constituents of the wax blanks used by the major companies. There are, however, quite a number of well-known formulae available, one of which is made up as follows:-

After the wax disc has been engraved by the recording stylus it is described as the master wax. A coating of the finest graphite is applied to its surface for the purpose of rendering it electrically conductive. It will be obvious that the surfacing of the wax master with graphite calls for the highest skill, otherwise the engravings might be distorted from their original position.

Plated Replicas

The wax master is now placed in an electrolytic bath and copper is deposited thereon until it is approximately 0.04 to 0.05 in thick; this process usually takes about 10 - 14 hours. The process may be speeded up by adding, say, oxalic acid or ethyl sulphuric acid, but generally such a procedure is not resorted to by the better-class manufacturers.

The copper master, as it is now called, is stripped from the wax, cleaned and given a coat of iodine stripping fluid so that the copper master may be easily separated from the 'mother', the manufacture of which is the next step to be taken. The copper master is placed in an electrolytic bath and nickel is deposited thereon to a thickness of 0.03 in. The copper and nickel plates are easily forced apart if the stripping solution has been carefully applied. Great care must be taken in handling the 'mother', because this is a positive plate, and the slightest movement of a track towards an adjacent track due to unskilful handling will cause a distinct echo in the completed record. The process outlined in respect of the 'mother' is now repeated for the purpose of producing what are known as 'stampers'. The 'mother' may be used over and over again for production of stampers. These plates are now often made by forming a chromium layer on the 'mother' of approximately 0.02 in thickness. The stamper is a negative plate and when this is locked to a hydraulic press and applied to the stock from which the gramophone disc is pressed the result is a positive disc, familiar to us all as the finished product.

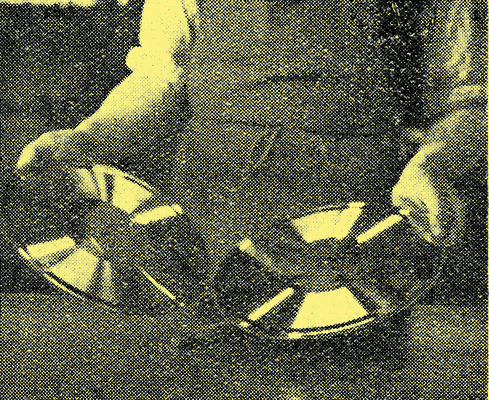

A nickel negative being separated from the copper master disc.

At this stage it is of interest to comment on the extraordinary fidelity and accuracy that may be obtained by electrolytic deposition. It is possible to obtain an exact replica in nickel of lines only 0.00002 of an inch in width.

The exact composition of any given gramophone record is generally regarded as a trade secret. A typical formula, however, may consist of:-

- button lac 25%

- slate dust 65%

- carbon black 5%

- cotton flock 5%.

lt is convenient at this stage to mention another type of commercial disc that has enjoyed wide popularity, namely, the laminated disc manufactured throughout the world under British patents. The laminated disc presents greater manufacturing problems than those produced from solid stock, but the finished product is superior. The method of manufacture is to supply a core of plastic material consisting of barytes, silica, powdered mica and any of the several binders. Two discs of Kraft paper covered with a 0.025 mm layer of fine thermoplastic powder made up as follows:-

- carbon black 5%

- barytes 35%

- copal 2.5%

- shellac 22.5%

- aluminium silicate 35%

are pressed one on each side of the plastic core, the surface material taking the impressions from the two stampers. During the pressing period the surface material on the paper does not move outwards, whilst the core material is forced out-wards. From the foregoing it will be readily seen that a very true impression of the stampers is obtained. The laminated record possesses a remarkably hard surface and consequently has a greater life, in addition to the fact that surface noise is lower than in other types of disc record. By using Kraft paper discs it is obvious that superior ingredients may be used in laminated records without unduly increasing costs, as the core of the disc is formed of the cheapest material, no shellac whatsoever being used in its manufacture. It is due to the fineness of the surface material that such excellent results are obtained with laminated records.

Radio broadcasting has demanded certain types of records to suit special circumstances. No doubt many of you have listened to recorded descriptions of events from broadcasting stations soon after the event had actually taken place. This means that a cheap and quick method of recording must be available. To achieve this end it is necessary that the actual disc on which the recording is done must be of a nature that permits it being used for reproduction purposes without any processing. Usually records of this type consist of an aluminium base carrying a coating 0.006 of an inch thick of nitro-cellulose lacquer. This material is sufficiently plastic to be easily and cleanly cut by the recording stylus, yet hard enough to stand the pressure of a reproducing pick-up. It should be noted that the needle pressure on this type of record should not exceed three ounces.

Recording on celluloid is practical but is not a very satisfactory process, the noise level being unduly high owing to the granular structure of the material. In addition, celluloid becomes hard and brittle, with the result that the stylus does not make a clean cut, and the noise level is increased under these conditions still further. If the cutting stylus strikes a hard spot, the edge of the stylus usually becomes damaged and a noisy track is cut from then on. As celluloid is hygroscopic, it may be seriously affected by weather conditions, and under such circumstances the sound tracks will be distorted in such a manner that reliable reproduction cannot be obtained from the disc.

One of the chief difficulties in recording on cellulose nitrate discs is that there is a tendency for the material to shrink with age, and to develop spots of unequal density. These spots are not readily apparent and it is not until the recording is completed that their presence is known. The stylus cutting through the cellulose nitrate and striking a hard patch will have its cutting surface damaged and the track cut thereafter becomes noisy as in the case of the celluloid disc.

At this stage a few figures will serve to illustrate how delicate are the engravings on a disc record and the strenuous conditions under which it is utilised. The width of the groove on the average English lateral-cut gramophone record is 0.006 in. The distance between the grooves when the cutting stylus is receiving no impulses from its driving amplifier is usually of the order of 0.004 in., and the depth of the groove is reasonably constant at 0.0025in. The groove wall has an angle of about 75 °, whilst the radius at the bottom is approximately 0.0025 in. The wall angle is, of course, controlled by the particular shape of the cutting stylus, which may vary between 60 - 90 °.

The length of the spiral groove on a 12 in disc may exceed 650 feet. This means that at the periphery the linear speed of the record under the reproducing needle is at the rate of 240 feet per minute, whilst at the end of the record the linear speed under the needle is down to approximately 86.7 feet per minute.

Consideration of the foregoing makes clear the difficulty experienced in recording and reproducing high frequencies towards the end of a record, assuming always that the recording commences from the periphery. With the standard gramophone record, the fall off in quality as the reproducing needle works towards the centre of the disc is readily apparent to the trained ear. Consider the problem from this angle. Assume that a recording commences from the periphery and works towards the centre, the last groove is cut two inches from the central spindle hole. At that diameter and at a speed of 78 RPM approximately 16 inches of groove pass under the reproducing needle per second. Now, if the groove has been cut by a stylus that was being modulated by a frequency of 5 kHz, it will be seen that the wavelength engraved will be only 0.0032in. in length. Now, when it is considered that the diameter of the ordinary needle is 0.003 in and its shape is being steadily distorted and its bearing surface increased as the needle wears, it will be readily appreciated that the needle experiences considerable difficulty in following faithfully the groove when high frequencies of the order of 5 kHz are being reproduced near the centre of the disc.

What actually happens in many cases is that the increased bearing surface of the needle causes it partially to ride on top of the groove, with the result that it cannot faithfully follow the small sinuosities, and as a consequence the output from the pick-up falls, resulting in what is termed 'centre fading'. If the recording were started from the centre we would have the advantage of a new and undistorted needlepoint that would be reasonably capable of following the closely packed sinuosities of a high frequency. As the wearing needle works out to the periphery the linear speed of the groove increases from 16 inches per second to 48 inches per second, resulting in increasing the wavelength of a recorded 5 kHz note from 0.0032in. to 0.0096in., thus affording the worn needle a better opportunity of following the groove sinuosities.

The question is often asked, 'Why do some recordings commence from the periphery and work towards the centre, whilst others commence from the centre and work outwards, and does either system possess any advantages over the other?' The conventional gramophone record the world over commences from the periphery and works towards the centre. A habit has been established, and in spite of the now known disadvantages of the system the manufacturers are not prepared to ask the public to learn a new trick, simple though it may be. If the technician had the final say in such matters, all modern records would commence from the centre. Not the least significant point favouring a start from the periphery is the fact that the most valuable area of a disc is that at the outer edge. A recording that commences from the centre, no matter how carefully rehearsed, may conclude a half-minute before the planned time, with the result that the best portion of the disc remains unused.

Records for Broadcasting

The gramophone record has played an important part in the development of radio broadcasting the world over and it is difficult to imagine broadcasting without the aid of recorded music and speech. The wealth of talent available in recorded form has made possible the broadcasting of programmes of great merit by stations that otherwise could never finance entertainment on so grand a scale.

After a decade of commercial broadcasting, we find that records are being especially produced for broadcasting purposes. The best known of these special productions are called 'electrical transcriptions'. Other types include the usual gramophone record, but carrying dramatic matter so arranged that record after record may be faded in to give the effect of an uninterrupted production of any length.

The so-called electrical transcription usually takes the form of a disc having a diameter of 16 inches and which is rotated at a constant speed of 33⅓ RPM. Discs of this type are capable of carrying high-grade programme material of up to 30 minutes duration on each side, still using the lateral-cut method of production.

At this stage a few remarks concerning reproducing needles will be of interest. In the first place, very few reproducing needles possess a sufficiently fine point to reach the bottom of the groove, but ride on the lower section of the groove walls. A badly shaped needle will ruin a record so far as high-class reproduction is concerned. It should not be taken for granted that every needle in a box is a good one, for this, unfortunately, is far from being the case. During the last four years shadowgraph needles have become very popular for reproducing electrical transcriptions or other valuable records. More often than not the owner of an electrical transcription will send a supply of needles with the record to avoid any chance of the record being damaged during reproduction. Shadowgraph needles are ordinary hard gramophone needles, but they have been individually inspected and their shadow projected on to a screen, when it is readily observed if they are distorted in any way. With the ordinary gramophone needle only an occasional needle is inspected, with the result that a number of distorted needles find their way on to the market, and many an excellent recording is damaged as a result.

Choice of Needles

Two important factors to be considered in connection with gramophone needles are the length and the compliance at the point. If a needle is over length when used with a conventional pick-up it has a tendency to whip, with the result that quality of reproduction is impaired and record wear is excessive.

The trailing needle, which is now quite a common sight in broadcasting stations, is used almost exclusively for reproduction of playback or positive-cut discs of the cellulose-acetate class. The trailing needle obviously presents a greater bearing surface to the record, with the result that the enormous pressure of 15 or I6 tons per square inch is reduced to 3 or 4 tons, resulting in less wear on the comparatively soft cellulose-acetate discs. It must, however, be borne in mind that high-fidelity reproduction is difficult to attain with needles of this type.

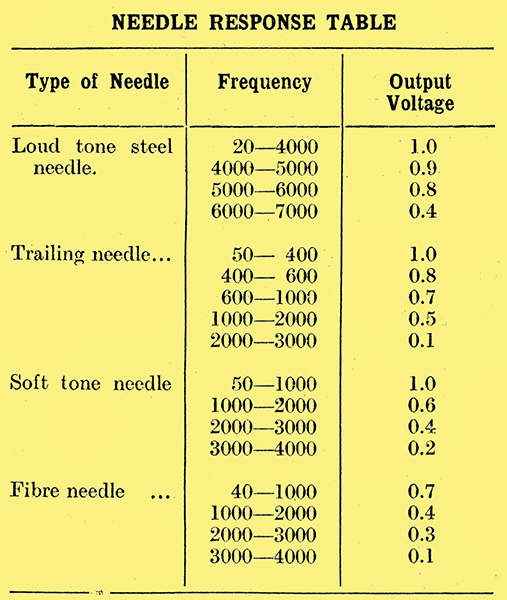

According to the type of needle used, so the output from an electromagnetic pick-up will vary. This is true when similar pick-ups are used and the material of which the records are made is identical. Another factor which would cause different output voltages from identical reproducing pick-ups and needles would be the material of which the record was made. For instance, two similar pick-ups would deliver slightly different outputs if both were reproducing tone at 1 kHz from two discs, one being the usual hard-surfaced gramophone record and the other being a cellulose-acetate disc. This would be true even if a similar wattage were fed to the cutting heads whilst the two records mentioned above were being recorded. The reason for the two different outputs so obtained would be due to the fact that the elastic modulus of the acetate is far higher than that of the usual stock from which the orthodox gramophone record is made. The variable outputs obtained by merely using different types of needles.are shown in the table.

Hill and Dale Recording

Previously all other references to records and recordings have been to the lateral-cut disc, which is now almost universal in its application. The vertical-cut disc, popularly referred to as the Hill and Dale method, possesses several advantages over the lateral-cut disc. It is possible to secure a slightly wider recorded frequency range than is permissible with a lateral-cut disc of similar dimensions. Hill and Dale discs may be safely cut with 200 grooves to the inch and, in addition, there is little difficulty in recording frequencies from 10 kHz to 20 kHz. At the present time the extended available frequency range is not of great importance, as few receivers are capable of faithfully reproducing this range. It should also be borne in mind that unless broadcasting stations operating on adjacent channels are widely separated geographically, there would be undesirable 'monkey chatter' if both stations were modulating 10 kHz cycles simultaneously. In almost all countries, broadcasting stations are located in the broadcast spectrum 9 or 10 kHz from carrier to carrier. In the vertical-cut disc the groove is cut to varying depths giving the appearance of a microscopic road crossing undulating country. The main factor limiting frequency in vertical-cut discs is the danger of the forces set up in the pick-up head exceeding the power that restores the needle to the bottom of the groove. It must not be thought that the restoring influence in this case is gravity, because records are made that have accelerations 800 times that due to gravity.

From the foregoing it will be seen that some mechanical restoring influence is employed to force the reproducing needle smartly down to the groove bottom, after the needle passes the crest of a hill. As a matter of interest it might be mentioned that the Edison cylindrical records were cut on the 'Hill and Dale' system. The Edison cylinder possessed one great advantage over all disc records, inasmuch as a constant linear speed is maintained throughout and such problems as centre fading were unknown.

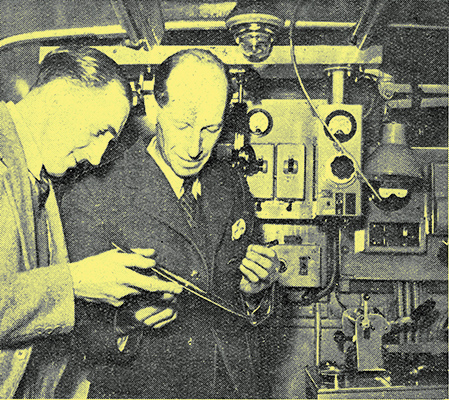

Examining a disc immediately after a direct recording had been made in one of the special vans used by the BBC for outside work.

|