|

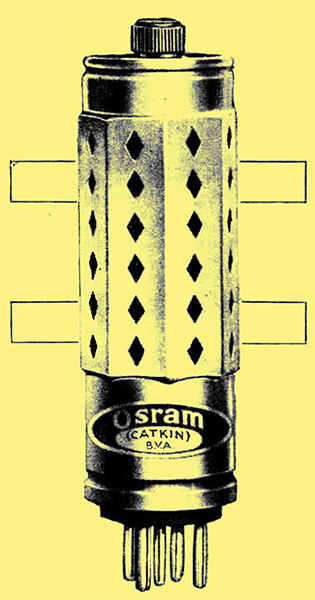

A radical departure in design. By resorting almost entirely to metal, instead of glass, in the manufacture of a revolutionary new receiving valve called the Catkin, the Osram and Marconi Companies claim to have achieved for the first time real consistency in valve characteristics. In other words, every Catkin can be regarded as a picked valve. The anode forms the external envelope in the new valve, which is almost unbreakable and non-microphonic.

Valve design is never at a stand-still. The steadily increasing figure for mutual conductance is, perhaps, to be expected, and the addition of an extra grid or so no longer creates surprise. Now we are to experience what is undoubtedly a most radical development in valve technique since the inception of the triode. The familiar form of valve with its glass bulb is soon to disappear. Its place will be taken by one of greatly reduced dimensions where the glass envelope is replaced by a metal cylinder which is actually the anode.

Valves in which the glass envelope has been replaced by a copper container represent, of course, well-proved practice in transmitting valves where water-cooling is directly applied to the anodes. Such valves are designated CAT (cooled anode transmitters), promptly designated 'cats' in laboratory slang. From this abbreviation is derived the name 'Cat-kin' as indicating the genealogy of the valve better than kitten; so Catkin was adopted as the name for the new miniature air-cooled version now to be available for reception.

An examination of the Catkin valve manufactured by Marconi and Osram supports the claims put forward.

Smaller Valve Losses

The spacing between the elements of a valve governs characteristic. If uniformity between one valve and another of corresponding type is to be maintained, accuracies of less than a thousandth of an inch are required in the disposition of the electrodes. Such precision is undoubtedly difficult to maintain when the only support afforded to the elements depends upon the critical setting up of wires embedded in glass. The Catkin has no such arrangements. First of all a robust steel clamp surrounding a mica insulator firmly holds the supporting wires. These wires are, moreover, straight, for it will be appreciated that where bent wires are used accuracy cannot so well be maintained. Next, the entire electrode system is located with precision within the anode envelope by mica spacing pieces. Thus the entire system forms a single and absolutely rigid unit as distinct from the comparatively meagre support which it is possible to provide for the electrodes in the glass type. This is the primary merit of the Catkin, accruing from which we may expect uniformity of set performance, and there will be no such thing as a 'picked' valve. To the set manufacturer valve uniformity permits of standardisation of receiver performance, and the correct working conditions will be maintained without the need for special testing of the initial set of valves. The rigidity of the electrodes and accuracy of spacing are claimed to be immeasurably greater than is possible in the valve of conventional design.

It cannot be denied that the flattened glass portion giving support to the electrodes is a source of losses. Glass is by no means one of the best dielectrics, and the time has come when attention must be drawn to the magnitude of the dielectric losses arising in the valve itself. The advent of tuning coils of very high efficiency has served to emphasise that the losses arising from the conventional type of valve are of sufficient magnitude to mar the superior merits of a modern tuned circuit. Bearing this in mind, in the design of the Catkin it was decided to abandon the glass 'pinch' and substitute mica as the insulator. It is true that the outgoing leads pass through a glass ring at the base of this new valve, but here they are set around the circumference. The resulting capacity between the leads is exceedingly small where we have glass as the dielectric.

Screen-grid and detector valves are nowadays, usually metallised. There is thus an earth potential spread over the insulating glass. preventing it from acquiring an electric charge. Metallising has the effect of reducing inter-electrode capacity, and, moreover, it prevents the setting up of stray electric fields which would otherwise arise between the charged globe and the surrounding leads, a condition which, if permitted, is a prodigious source of hum in mains receivers and a common cause of spurious back-coupling.

The electric field within the anode of the Catkin valve is entirely uninfluenced by any surrounding charges, and the electrons cannot build up unwanted potentials which might interfere with the field within the electrodes.

Better Screening

Should circumstances demand it the signal potential on the anode of the Catkin may be prevented from creating stray coupling by the provision of a tubular metal screening cover shown in the top photograph. The inclusion of this outer screen is optional. It extends over the valve from top to bottom, and, like metallising, is connected to the cathode in the case of mains valves, but has the additional advantage that it embraces the outgoing leads at the base. This outer screen is perforated to afford ready dissipation of heat and its octagonally flattened faces prevent it rolling. Being parallel sided, quantities ot valves occupy much less space than hitherto.

In the exposed anode type a coating of black enamel is applied giving sufficient insulation to prevent shock should one accidentally touch the high-voltage anode. It will be appreciated that the generous heat dissipation afforded by the. Catkin design gives cooling for the grid as well as the anode. Conditions are very different in the glass type, where the large surrounding vacuum presents the difficult problem of getting the heat away where dissipation by convection or conduction is non-existent. Effectiveness of cooling does, of course, to a very large extent, govern the rating of output valves.

Present-day sets with enormous overall gain are very prone to what is commonly called 'howling', which arises from the sound vibrations causing movement of the electrodes, usually in the case of the detector valve. By virtue of its rigid construction the Catkin is not likely to be influenced in this way. As a further precaution, however, the valve is secured to its base ring by a rubber clamp, and the sound conduction path is limited to the thin conducting wires joined to the valve pins. It is well known that rubber is the only sound insulating material which will provide a non-microphonic mounting, and we now have, for the first time, an effectively sprung clamp, and this is independent of the valve holder. A non-microphonic mounting is of vast importance when the set, as is now commonly the case, takes up a position immediately behind a single or perhaps dual loud speakers, into which the output valve delivers several Watts.

Wireless is now finding its place as part of the equipment of the car, and the Catkin valve, being uninfluenced by vibration, whilst being robust and compact, has attractive possibilities for car radio. In this connection, in addition to durability, it should be noted that a new form of filament-cathode design has been adopted, which permits of a 10% fluctuation of heater potential, thus allowing for the voltage variation of the car battery. Compactness is another important advantage in this application. The much reduced size of the metal envelope as compared with the glass counterpart is an important feature in the prevention of direct coupling with the sound output of the loud speaker.

Some valve users have experienced trouble due to the glass bulb breaking away from its Bakelite base. Fracturing of the cement in this way is a weakness of present valves, and it is interesting to note that no form of cementing is employed and a loose cap becomes an impossibility.

Copper-to-glass Union

The Catkin valve is practically unbreakable, and may be dropped from a height of several feet on to a concrete floor with but little risk of damage either by fracture or by derangement of the critical spacing of the electrodes.

The copper-to-glass union is an interesting feature of the new valve, and it is a creditable achievement to produce a gas-tight seal under mass production methods. In order that the vacuum may be well maintained in a valve, excessive temperature rise for any prolonged period must be avoided. All metal parts within the valve are, of course, gas-freed at a high temperature. but in the course of manufacture the glass bulb in a conventional valve is a prolific source of gas and necessitates prolonged de-gassing.

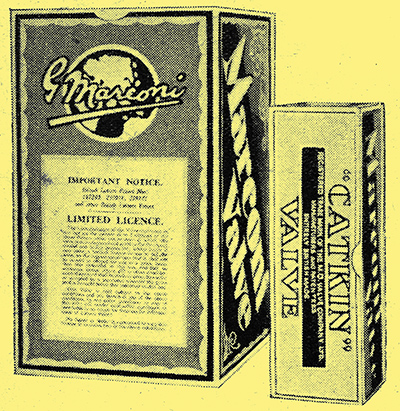

Catkin equivalents of the MS4B, VMS4, MH4, and MPT4 will make their appearance on the market almost immediately. These are the types which are in most general use, and it is the intention of the manufacturers to add to this range shortly. The characteristics of the Catkin valves follow those of the glass equivalents and for which they serve as replacements.

The four types issued are those adopted in the more popular sets, so that in many cases immediate advantage can be taken of their use.

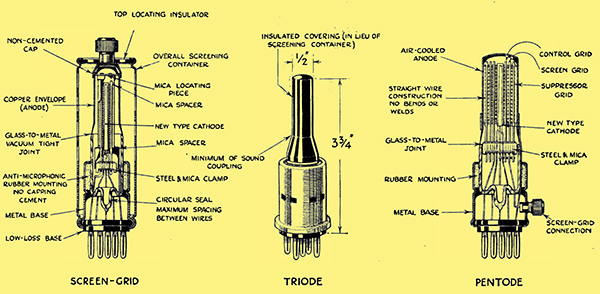

Drawings to illustrate details of the new valves

Uniformity of characteristic, compactness, generous cooling and reduction of base losses are the essential advantages afforded in this revolutionary valve design. There is a screening cover to the SG valve, but with the triode this is optional.

More about construction - a practical test.

Catkin valves when packed occupy about one sixth the space of their glass counterparts.

If one were to penetrate the fastnesses of any of the service departments of the large wireless set manufacturers and were to enquire what was their chief activity, the answer would undoubtedly be valve replacement. Although called upon to fulfil the most complicated function in a receiver, the valve, unfortunately, is one of those component parts which lend themselves least to modern manufacturing methods.

Details of the unscreened SG valve showing the rubber mounting.

The use of glass for the bulb and pinch makes close tolerances for these parts difficult, and so from sample to sample there may be slight variation in performance. The glass container, with its irregularly gettered surface, provides a source of electric charges of indeterminate value which may influence to a slight extent the fields between the electrodes. Incidentally, the glass bulb is fragile increases bulk, and is a hidden source of gas. The glass pinch of orthodox design has to accommodate so many leads in such a small space that there are measurable capacity effects. Furthermore, the capacity is not pure, and can be looked upon as a capacitor having a resistance of high value shunted across it.

The triode and pentode (unscreened). The rapid cooling of the anode in the case of the pentode gives an increased AC Watts dissipation.

By almost entirely eliminating glass and introducing an all-metal construction into their new Catkin valves, the Marconi and Osram companies have instantaneously removed these and a number of other disadvantages. Not content with this complete breach of tradition, the makers have also made radical departures from the conventional in electrode assembly which have resulted in a hitherto unattainable consistency of characteristic and a considerably greater robustness.

A Catkin screen-grid valve without any packing whatsoever has survived the return journey by post from London to Aberdeen -an ordeal which, without offence to the Post Office, involved more man-handling and rough usage than an ordinary listener would give it during its life.

Tested in a Receiver

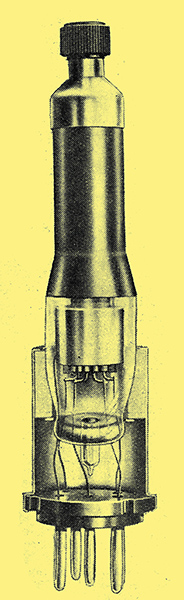

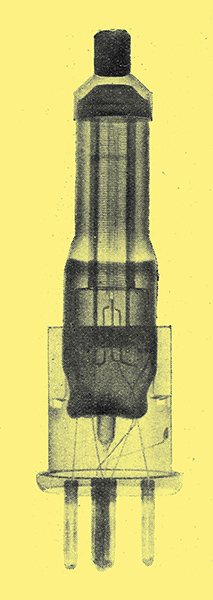

An X-ray photograph of the screen grid valve which clearly shows the rigid support given to the electrode assembly.

Although the electrical characteristics of the new valves are nearly the same as those of their glass counterparts, it was anticipated that the collective result of so many mechanical improvements would mean that a receiver in which these valves were substituted would give a better all-round performance. An experimental superhet was fitted with Catkins, and it was at once apparent that the number of whistles had been reduced pointing to a welcome reduction of those harmonics brought about by curvature of characteristic. Each. valve in the set could be tapped with the metal end of a screwdriver and practically no microphony was observed.

As an oscillator the MH4 gave normal results, and the reasonably long grid base of the VMS4 proved quite satisfactory for AVC. General sensitivity was above normal, this being probably due to reduced valve base losses and therefore decreased damping of the various tuned circuits. The Catkin pentode was a distinct improvement over the glass type, and approximately 3 Watts speech output could be safely extracted from it owing to the greatly improved cooling of the anode.

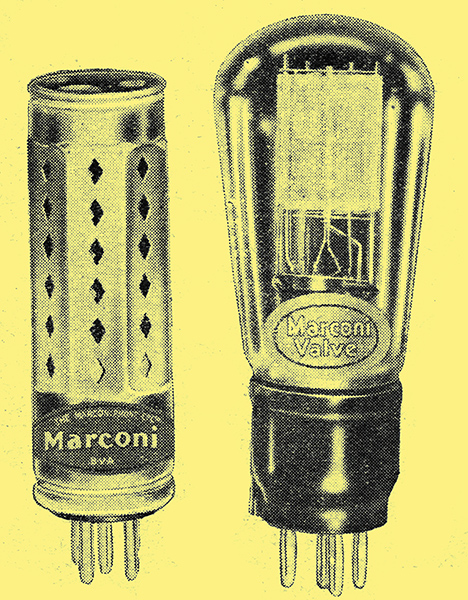

A screened Catkin compared with a glass-bulb valve of similar type.

|