|

No two valves are perfectly matched, the variables in manufacturing see to that. Valves from the same production batch will match quite closely and a pair can be selected that are virtually identical to be used as a matched pair.

The expression today is that 'gain is cheap' and in this context an operational amplifier circuit is defined by the passive elements of the circuit and not by the open loop characteristics of the device. Negative feedback is used to make the circuit reproducible in-spite of any variations in the performance of the active devices.

In the valve era gain was anything but cheap, and active devices were worked to their limits in many circuits. It was this need to extract the maximum from the valve that made minor variations in characteristics so influential in whether a valve functioned correctly in a given application.

From a given manufacturer and assembly plant the spread of characteristics will be small and this is the normal expectation when replacing one valve for another.

Manufacturers, and larger customers, track batch codes and assembly lines for quality control. This is particularly true in military applications where the valve could be employed close to the design limits of the type.

Governments and large customers require a stable source of supply and will often insist that a given design is manufactured by more than one company to ensure adequate and reliable supply. The UK Government CV series introduced in 1941 was created for just these reasons. If a valve was designed to a requirement specification then the Government could insist that several manufacturers commenced making to the same specification and drawings. The CV type could be an exact match to a commercial valve or a subtle variation of that original design. Some companies were better at some processes than others and a given valve from a particular manufacturer would be the valve of choice for the engineers working on the project.

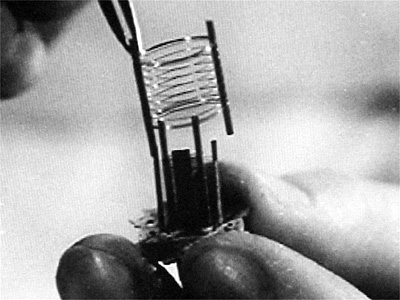

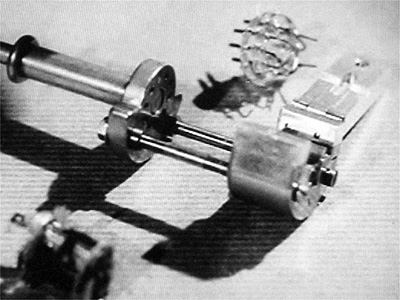

Valve manufacture is a complex process with automated processes and hand assembly combined into the final product. The individual components are had assembled into a jig and fixed into place within the jig. Very often a series of jigs are used in the hand assembly stages. In this way variations are introduced by operator accuracy, jig design and fixing process.

Beyond valves that were planned to be identical as far as possible are valves that were popular and copied by competing manufacturers. These copies could not be exact unless the technology was being shared, such as when a pair of companies would offer a customer a joint supply. Design copies were 'sensibly equivalent' in typical circuits and quite interchangeable.

In other cases one commercial design would work quite happily in circuits that were based on other valves. Especially in the early years where production tolerances were wide and most similar types were interchangeable.

Some valves are 'pin compatible' with another valve. The ECC81, ECC82 and ECC83 are all pin compatible but except for a few applications they are very different devices, and would not be considered interchangeable.

In our listings we have placed as 'equivalent' all valves that work the same way in general circuits. Also top quality valves may appear as equivalent to a general commercial type, but when looking at the special quality valve the commercial type would not be deemed a replacement. Check the actual specifications before substituting.

A further complication that we do not address is when a successful design is re-engineered for a new base or envelope. This happened in particular when the octal valves of the 1930s and early 1940s were made available in miniature all glass versions. Where we have the information it will appear in the exhibit text. eg The 807 and the 5B/254M.

|