|

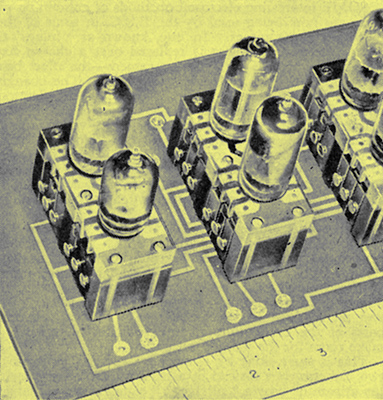

Part of a working circuit using the experimental cellular assembly technique. Each cell is fitted with a small knob and the blocks are spaced far enough apart to allow the cells to be withdrawn.

Printed circuits, in which conducting patterns etched on plastics take the place of conventional wiring, have come into fairly wide use. For the problem of connecting components and valves to the printed sheets several solutions have been offered. However, the diversity of these solutions and their inability to gain widespread acceptance indicates that the right answer has not yet been found.

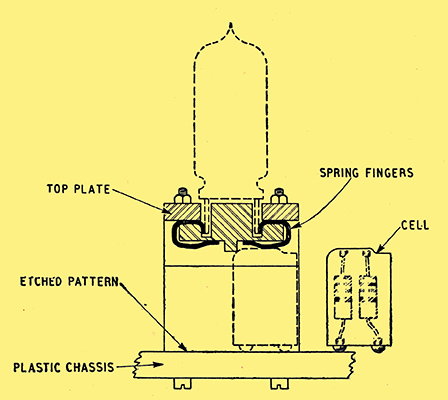

In a novel approach to the problem made by the US National Bureau of Standards, small three-contact moulded blocks or cells, each containing one or two circuit elements - resistors, capacitors, inductors, are pressed against the etched circuit pattern by means of springs that are extensions of the valve socket contacts. No soldering is needed. The individual moulded cells are about 0.875 in high by 0.5 in wide by 0.25in thick. Each has three contacts, one on the top and two on the bottom. The cells are grouped together in 'building blocks', each comprising two valves and twelve cells held in a compact bundle by means of a suitable frame. The top surface of the block consists of a spring assembly containing the valve sockets and the necessary spring contacts. When the block is fastened to the printed base plate by means of screws, springs in the spring assembly apply substantial pressure to the top terminal of each cell and hold the two bottom terminals firmly in contact with the printed circuit pattern. Positive and noise free electrical connection is further assured by the application of a thin film of grease to the cell contacts.

The two-valve block is considered an optimum sized sub-assembly in the new system. Any number of the blocks can be mounted on a suitably printed base-plate of sufficient area. Potentially inexpensive, they are compact (about 2.25 in x 1in x 0.186 in, not including the valves) and are easy to store and to handle. They are extremely rugged, and as long as a block is secured to the base-plate none of the cells can vibrate or shake loose.

A noteworthy feature of the technique is that it enables both blocks and cells to be replaced quickly without the use of plugs or connectors. If conventional plug-in assemblies were made as small as these blocks the plugs would add substantially to both size and cost. The elimination of both soldering labour and multiple connectors results in a double saving.

In case of trouble, an entire block can be easily removed for repair or replacement, simply by loosening the screws that hold it to the base-plate. Either on the spot or after return to the factory or servicing department, defective blocks can be quickly repaired by replacing faulty cells. Each cell is identified by suitable markings.

An important aspect of the use of three-terminal cells in the new technique is the fact that positive pressure can be maintained at three points, and only three points, by a single spring. Fortunately, in the great majority of electronic circuits no more than two circuit elements need be connected electrically to a single valve electrode. A three-terminal cell, therefore, besides being easy to hold under firm spring pressure, will in general provide enough electrical contacts for the elements associated with any valve pin. Exceptional cases can be taken care of in the new system by providing for a spare cell not connected to the valve pins. It is also possible to provide for three-terminal cells of double or triple the standard thickness to accommodate occasional oversized elements.

An experimental nine valve cellular circuit already constructed at the Bureau appears to confirm the practical possibilities of this type of construction. For convenience, the limited number of cells needed were formed at room temperature using a casting resin, although this is not the best material. For quantity production, cells could be moulded in phenolic by the process now in wide use for making resistors and capacitors. The components would be spot welded together and to the terminal tabs before moulding.

Constructional details showing how the cells fit into the blocks.

|