|

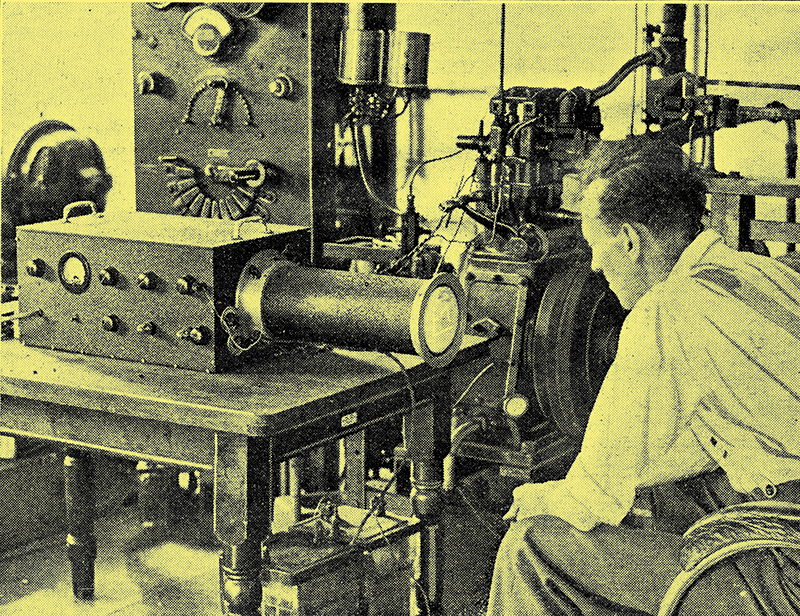

Experimental cathode ray equipment, for investigating problems relating to internal combustion engine fuels.

A new application to the problems of fuel blending.

New applications of the cathode ray oscillograph are of almost daily occurrence, but one of the most interesting which has recently appeared is in connection with the testing of petrol and oil fuels for internal combustion engines. Many readers will already be acquainted with the fact that the 'anti-knock' properties of fuels are becoming of increasing importance now that the car manufacturers are making an all-round increase in the efficiency of their small high-speed engines. The standard method of test is to burn the fuel in a special type of variable-compression engine, the incidence of detonation or knocking being detected by an instrument known as the Midgley bouncing pin. This method, although accurate, is admittedly arbitrary, and while it indicates the highest compression which can usefully be employed with any given fuel, it gives little insight into the phenomenon of detonation.

At the Anglo-American Oil Company Research Department at Vauxhall the cathode ray tube has been successfully applied to this problem and results of far-reaching importance have been obtained. The voltage used to deflect the spot in the cathode ray tube screen is obtained across a compression-type resistance actuated by a small steel diaphragm let into the cylinder head. The type of resistance element employed gives a linear relationship between pressure and the volts developed, which are applied to give a vertical deflection. A normal time base circuit, triggered by a contact on the engine shaft, supplies the horizontal deflection. Due to the persistence of vision, a complete picture of the pressure variation throughout each cycle can be obtained, but the beauty of the scheme is that, by altering the time base, any section of the indicator diagram can be enlarged for detail inspection of transient effects, particularly those in the vicinity of the firing point. It is for this reason that the DC amplifier connecting the resistance element with the deflecting plates of the tube has been designed to eliminate all resistance- capacity effects with their associated time constants.

The same technique has also been applied to the investigation of the movements of the pintle in the spray jet of Diesel engines and has opened up new channels of attack on the special problems associated with this rapidly developing type of engine.

|