|

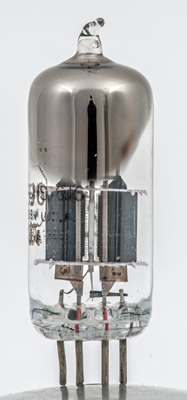

In a batch of valves was a 6J6 with the evacuation pip broken off and an ideal candidate for dissection.

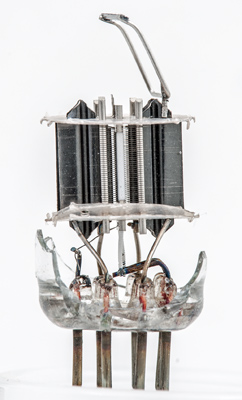

The envelope was wrapped to prevent glass splinters escaping and the tube tapped with a hammer. The glass was tough and did not break. The use of a bolster chisel another tap from the hammer removed most of the glass. The tube had shattered and the wrapping was thus a sensible precaution.

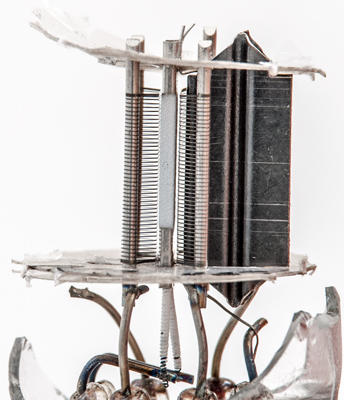

Newly exposed with nothing removed.

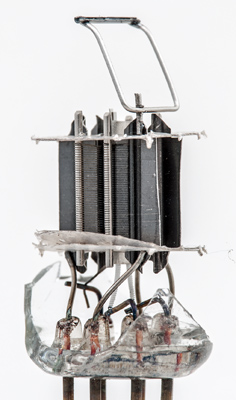

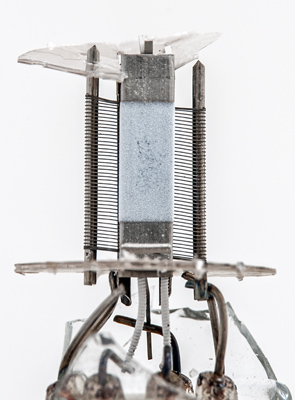

The anodes are made of very thin sheet.

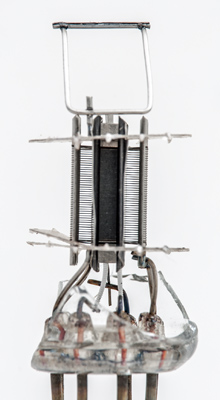

Looking directly into one anode with the grids beyond.

The getter holder is a U shaped channel 9 99 long and 0.5 mm across. Some of the raw getter material remains within the channel.

With the getter holder removed the top mica could be twisted to allow one anode to be removed.

The small anode was picked up by a magnet and thus confirmed to be made of nickel sheet. The working face of the anode is 8.42 x 3.2 mm.

The shaped grid allows the anode to get close to the winding.

A closer view of the central rectangular cathode tube with the coating over a reduced area.

The cathode coating has been sprayed all round the metal.

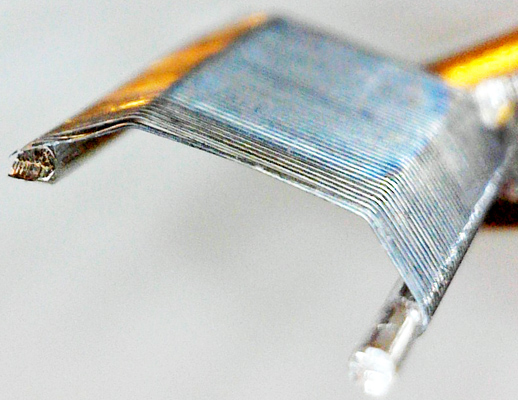

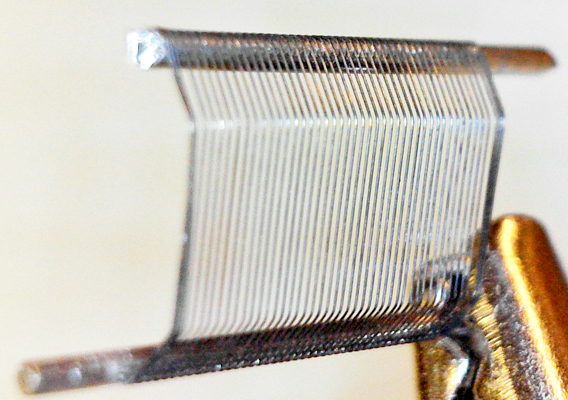

One grid showing the shaping.

Across the supports the grid measures 6.8 mm.

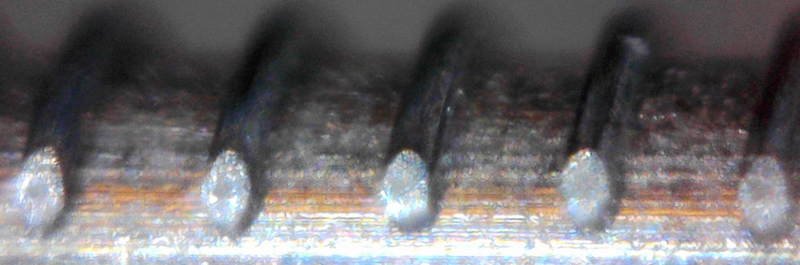

The original winding looks to have been pressed into shape after the wire has been cut.

The winding is 8.44 mm from top to bottom. Within this length are 41 turns giving a pitch of 0.206 mm.

Close-up of the grid wire showing some corrosion.

Here the clean cut of each piece of wire can be seen.

The grid was probably wound on a lathe with notch and peen to secure each loop to the support. One half of the winding is then sheared off and the remaining grid pressed into the correct shape.

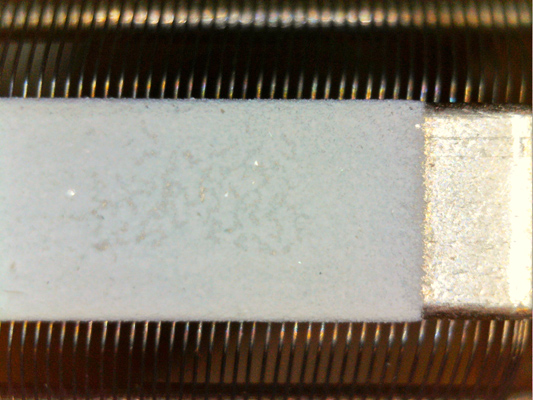

Close-up of the cathode coating.

Looking at the edge of the cathode tube, the coating is sensibly uniform. The cathode tube is 3.0 mm wide and 0.78 mm thick.

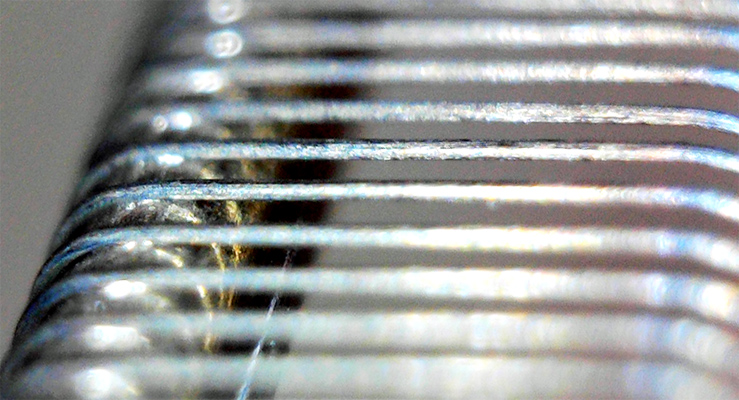

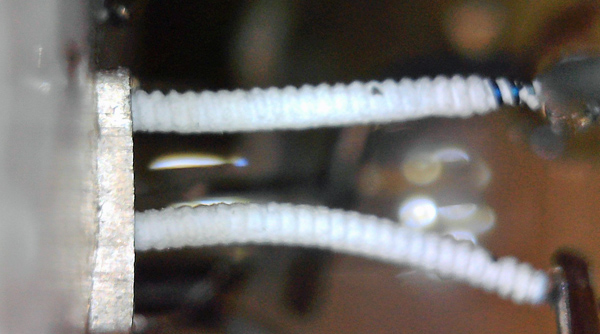

The insulated heater.

Heaters are wound on a mandrel that is subsequently dissolved away leaving the helical wire with gaps between the turns. The insulation looks to be sprayed on rather than dipped as it is uniform in thickness.

|