|

The 1935 RCA Octal base was first used on metal envelope valves and was designed to standardise valve base design. In the UK a move to adopt the new Octal base by the BVA failed. Mazda designed an Octal base with a larger spigot to improve the protection to the evacuation tube. Mullard (Philips) preferred the American design, probably for international commercial reasons, and Mazda were the only company to use their design. It was initially named the British Octal but became known as the Mazda Octal (MO). The RCA design became known as the International Octal and became the standard base until the all glass valve came into general use.

The RCA metal valves used a pressed hard glass disc to allow the connections to pass from the vacuum to the outside. It was formed from a short length of tube that was softened by gas flames and then compressed around the pins. To avoid stress on the glass the external leads were wires that were subsequently soldered into the visible pins in the Bakelite base plate.

The B7G base was developed in 1940 by RCA to reduce valve size and manufacturing cost. The machinery that made the glass disc for the metal valves was adapted and the external wires were replaced with pins. Initially the pins were reduced in diameter just under the glass so that and bending force would bend the wire and not damage the vacuum seal.

The mid 1930s and the war years mark the emergence of the American industry as the dominant force.

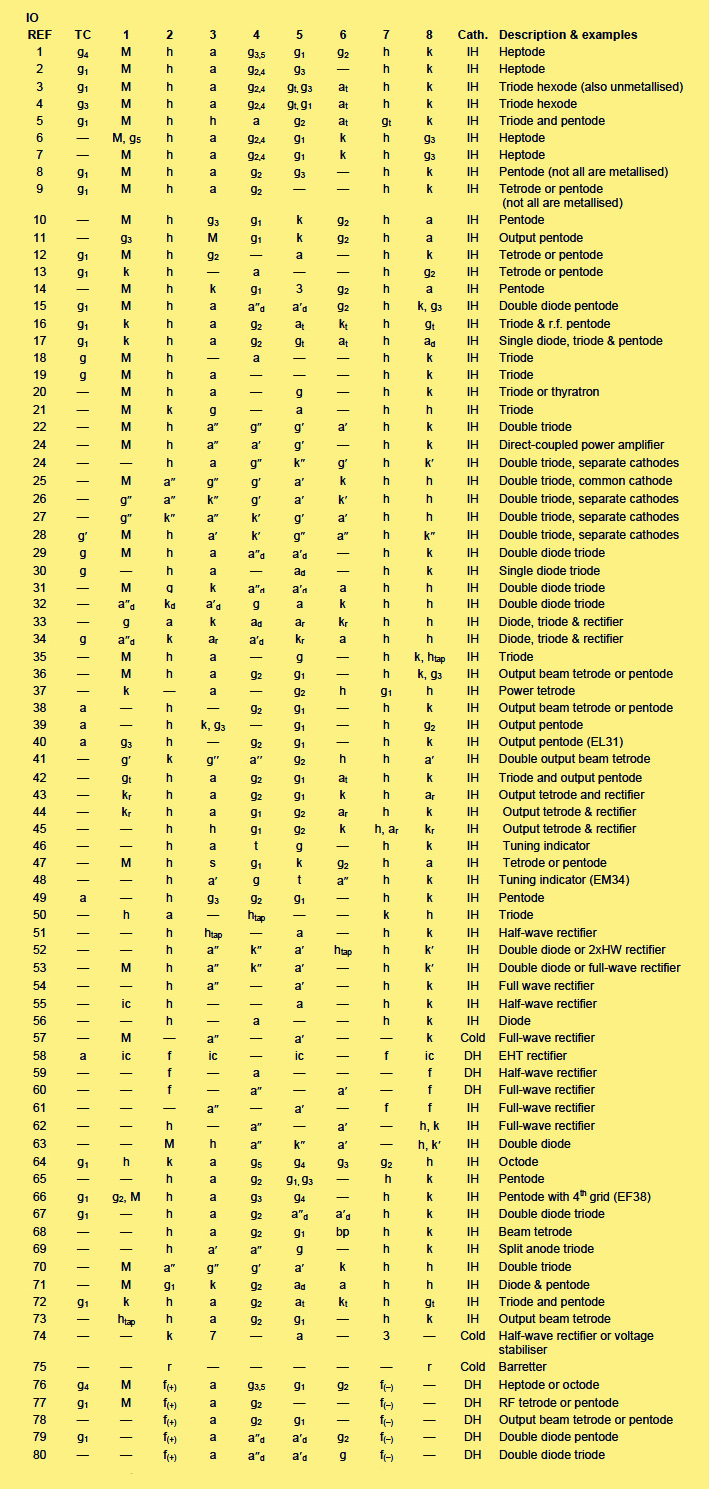

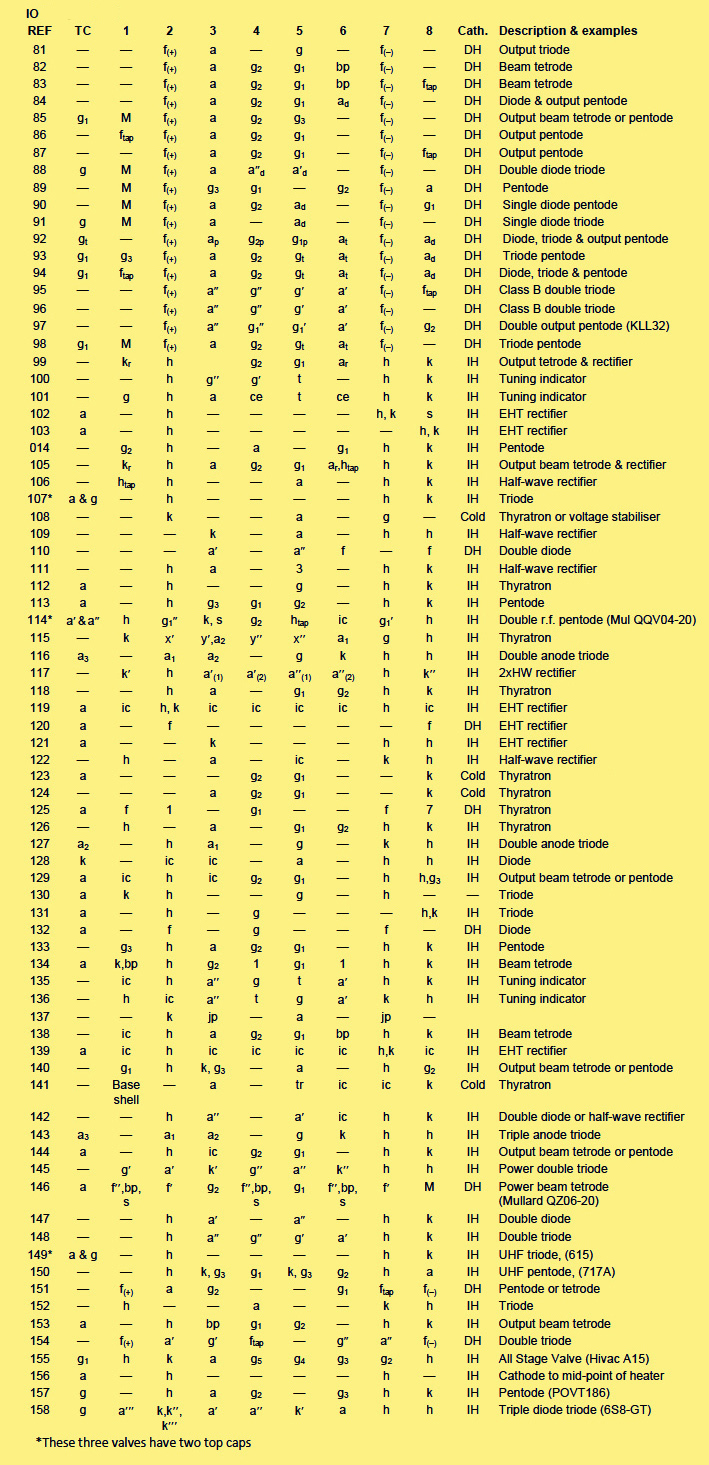

The pin-outs below refer to the data researched by Keith R Thrower OBE.

|