|

The P1 carton

Alfred Charles Cossor (1861-1922) founded a small scientific glassware business in Clerkenwell (London) in about 1890. Alfred Cossor was a craftsman and his business produced specialist instruments including Crookes tubes and X-ray tubes. In 1902 the first British examples of Braun cathode ray tubes were made by them.

With the advent of Fleming's experiments into diodes in 1904, specialist glass-blowers were required to make the different samples. Cossor was believed to have been involved in the manufacture of some units. This was their claim to being the oldest valve makers in the world.

A C Cossor as a private company appeared in 1908. In 1918 with a rise in business, in part with war requirements, the company moved to Highbury to a plant known as the 'Aberdeen Works'. It was here that the valve business was concentrated.

During the Great War Cossor was heavily involved with valve manufacture. After this time they made a wide range of valves for receivers and a limited range of valves for transmitters.

The Early Cossor valves, the P1 and P2 that went into production in 1922, had parabolic anodes with fan shaped grids and arched filaments. It is thought that this design was originated to avoid the Marconi patent for the cylindrical grid and anode.

In 1924 Cossor introduced their Wuncell range of valves. These were the first British designed valves to feature an oxide coated filament. Sadly, the oxide coating did not demonstrate good reliability.

Cossor introduced their Point One range in late 1926 this consisted of: Det & LF, HF, HF & Det, LF, Plain Top, RC and Red Top. Also introduced were the Stentor Two, Stentor Four and Stentor Six reflecting the three standard filament voltages of the time.

MOV had a shareholding and board representation within Cossor, and, therefore, were aware of the companies activities and developments. In return Cossor had access to the M-OV patents from about 1927.

Cossor replaced its Point One and Stentor ranges in 1927 and introduced the diamond label proclaiming 'New Process' perhaps a benefit from access to M-OV technology.

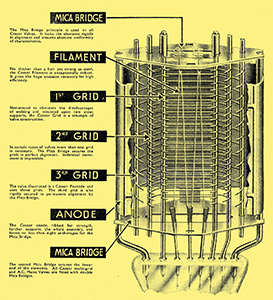

Construction diagram from December 1932.

In 1930 Cossor introduced the first British RF pentode, the MS/PenA. The anode impedance was low and was not widely used, but it predated the main introduction of the RF pentode by three years.

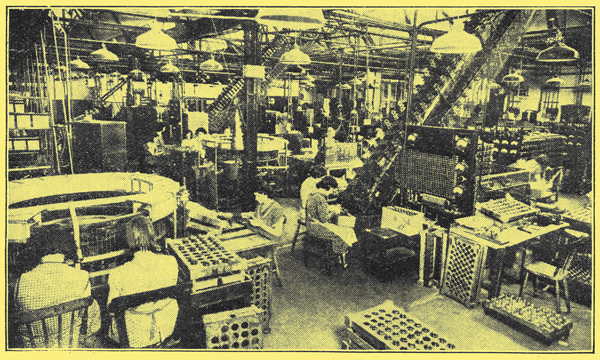

One of the battery valve sections at the Cossor works in 1934.

During the 1930s they did much pioneering work in designing oscilloscopes and the CRTs for them. They also designed and made EHT rectifiers such as the SU2150A for use in CRT power supplies. Because the Cossor works tended to employ skilled glass-blowers rather than just factory girls, and because they were designing for a very limited market, the Cossor EHT rectifiers were designed to be hand made. Although naive looking they were electrically robust and entirely successful in their intended application.

Cossor's supplied almost all the service oscilloscopes supplied to the British Services (especially the Navy) before WW2. During the war the increased demand for service oscilloscopes exceeded Cossor's manufacturing capacity so some of the work was farmed out. Both Mullard and MOV manufactured supposed equivalents to the SU2150A but in each case the valves were redesigned to suit factory production methods. The results were not excellent, having relatively short lives and being easily damaged when EHT faults occurred. The Navy insisted on the real thing and since they went on using Cossor oscilloscopes into the 1970s, long after Cossor ceased to make its own valves, the Naval Stores organisation purchased and hoarded very large numbers of spare valves, including SU2150As.

Cossor became a public company in 1938, and reorganised in 1945. In that reorganisation, Electronic Tubes Ltd (ETEL) was formed as a subsidiary.

The final chapter of this famous name was that EMI acquired a controlling interest in the business in 1949.

Cossor continued to manufacture and market domestic radio and TV sets for several years after they had abandoned mass-production of consumer valves. They simply bought suitable valves from other manufacturers and branded them with the Cossor label before supplying them in sets or to the trade. Cossor were members of the BVA cartel and one of the rules was that members should not poach each others' type numbers. Each BVA brand therefore had to use its own unique type numbers even where the valves themselves were identical. However, there was (at that time) no rule against using American type numbers provided the valves concerned were interchangeable with their American counterparts. See 6AJ8

In 1961, after making losses, Cossor was acquired by Raytheon.

|