|

not the Valve that Won the War

That honour of course probably goes to the EF50 (and its various service codes) for its role in allied radio and radar equipment during World War II. The EF91 was an unromantic 'workhorse' valve made by the million and designed into umpteen TVs, radios, transmitters, pieces of industrial equipment and test gear. Like the EF50, it has a story worth telling.

Just after the war there was a need for a compact, high frequency pentode for use in the RF and IF stages of the new TVs being designed to benefit from the resumption of public TV broadcasting in June 1946. For lower production costs and compactness the all-glass B7G 'miniature' envelope (17mm in diameter and 46mm tall, excluding the pins), released in the US in 1941 and first used in the 9001/9002/9003 series of valves designed for use at UHF, was the natural choice. The resulting valve, which we commonly refer to now as the 'EF91' (see later for a discussion of whether this was the first incarnation) was produced and consumed in vast numbers, helping to satisfy the demand for TVs in the late 1940s and early 1950s. In correspondence with Philip Taylor, he believes valves using the B7G envelope were probably first manufactured in the UK by Mazda in about 1943, presumably using machinery shipped over from the US.

The Humble EF91 and its Aliases

So far I have referred to the valve as the 'EF91', which is certainly the generic name by which the valve and its many equivalents are known today in the UK. In the US the valve is commonly known as the '6AM6'. From this distance in time it's not clear whether it was the EF91 itself or one of the valves that we regard as being its 'clones' which appeared first: it may well be that the 8D3, the 6F12, or even the Z77 or 6AM6, was the first 'EF91' to reach production.

It's tricky to pin down the exact date of introduction for the EF91 and its equivalents, but judging from the first production dates in 1948 of several TVs using the 6F12 and Z77, it must have been sometime in 1947 that the valve first appeared in prototype volumes and was being tested in newly-designed equipment. It was probably the Murphy V114 TV that has the honour of being the first commercial set that used Mazda 6F12s (as RF amplifier, sound and vision IF amplifiers, and video amplifier) sometime in 1948.

V114 TV (click image to enlarge). This image is taken from Murphy Radio

The V114 is often considered to be the first new TV designed in the UK after the war. The EF91 (along with a few EF50s) was probably first used in the Philips 383A TV, launched in September 1948. A clutch of Z77s appeared in the Baird T163 TV in 1948. By 1950 the EF91 was well established, and there were many of them in the early Bush TV22 and TV24 sets.

The EF91 was designed as a high gain, high impedance, screened pentode, and became the universal valve of the late 1940s and the 1950s, as can be seen by the large number of manufacturers who made direct equivalents. Mullard described the EF91 as a 'Miniature RF pentode primarily intended for use as RF and IF amplifiers, or mixer valves in television receivers'. In fact it could be used from AF to VHF up to about 200 MHz, and because of its versatility and low cost, quickly found itself designed in large numbers into most types of electronic equipment, especially into TV sets of course, its original intended application.

In TRF and superhet radios it was used for RF and IF amplification, for oscillators, frequency changers and multipliers, detectors and audio amplifiers. The famous Racal RA-17 receiver, numerous pieces of professional test gear, some Eddystone receivers, and of course many TV sets designed from about 1947 onwards used the valve. The Swiss Radiomuseum., run by Ernst Erb (HB9RXQ, EA8BGN), is a useful way of searching for the use of a particular valve (or transistor) in radios or TVs.

The Many Equivalents

In Europe you are likely to find EF91s (and equivalents) manufactured by GEC, Osram, Mullard, Marconi, Cossor, Brimar, Mazda, STC, Chelmer, to name just a few. Consequently the EF91 has many aliases, including the Z77 (Marconi); 6AM6 (Brimar and many US manufacturers); 6F12 (Mazda); 8D3 (Brimar, until they recoded the valve as a 6AM6); 6064 (Brimar special quality version of the EF91); M8083 (Mullard special quality version of the EF91); and 5A/189K (STC). If that's not enough for you there are also the 5A/160K, 6024, HP6 and V888 which are also candidates for EF91 equivalents, but about which no firm information has been tracked down so far.

There are several 'service' versions of the EF91, including the CV138, the rather strange CV2001 (see more about this valve later), CV2195, CV4014, CV5377, CV10327 and maybe a few other CV numbers.

Identity Parade Line up

The image above shows an 'identity parade' line up of EF91s and several of its aliases, including some service equivalents. When you're looking for an EF91 for a project, any of these valves should do the job, and often valves are marked with more than one number: for example I've seen Mullard valves marked EF91 and 6AM6. I particularly like the bluish colour of the glass around the anodes in the Mullard valve.

Above: the 'classic' pose of the Mullard EF91. The reason for this bluish colour is interesting and was discussed recently on the UK Vintage Radio Repair and Restoration forum.

Inside the EF91 (and many similar valves) the anode runs round only part of the cathode/grid structure, and so a significant number of electrons pass through the grids and the gaps in the anode, and into the glass envelope. It was found that this gradually caused gas to be released from the glass, and over the extended lifetime of high reliability valves required by, for example the GPO, it was sufficient to impair the efficiency of the valve and to shorten its life. Therefore, the centre part of the glass envelope was coated (by vacuum deposition) with a chemical. This kept the electrons from the glass and thus reduced the gas released, and thus lengthened the working life. The actual colour of the coating varied with the temperature of the firing, and has no significance.

Some manufacturers of 'EF91s' use a different technique to protect the glass from these stray electrons. For example, I've seen some M-OV CV138s with what appears to be a metallised internal coating.

CV Valve Codes

I'm not going to reproduce the CV list here, it would take up many pages of the magazine and the editor wouldn't thank me for it, but when you look at such a list (See 'Radio Valves and Tubes - 3 Military 'Common Valve' (CV) Equivalents' by Geoff Arnold. Radio Bygones No 11, June/July 1991, or on-line) you can see that related valves were often given sequential CV numbers. For example, the range CV1929-CV1958 covers the 6Hxx, 6Jxx, 6Kxx, 6Lxx and 6Nxx variants in sequence of their non-CV numbers.

CV codes don't give a clue as to the function and 'civvy' identity of a valve (maybe that's intentional), and as such aren't really a coding system but a more a serial numbering system. But there are other markings on these valves which help identify the manufacturer and production date.

CV Manufacturer Identification

Although CV valves usually don't have the manufacturer's name printed on the envelope there is a coding system that documents the date of manufacture, the manufacturer, and the precise location. Because different stages of the manufacturing process could take place at different locations, it is the site of the valve's evacuation, that is where the vacuum is created, that is used.

There are several on-line lists of these manufacturers' code, but I think the most comprehensive one was at the Tubecollector site. This also explained the date coding system on CV valves.

Briefly, the date code was made up in one of two ways. A four digit code was made up of the last two digits of the year followed by the number of the week in the year starting at 01. Thus 6407 indicated the 7th week of 1964. Alternatively two letters were used. This was used up to January 1st 1965. In this scheme the first letter A = 1945 and so on, and the second letter A = January and so on. Letters I and O were not used. Therefore AA = January 1945, NF = June 1957, etc.

EF91 Applications

Before I plod on and look in detail at some of these EF91 variants I thought it would be useful to explore some applications the valve has been put to, outside its intended career in TVs. In December 1954 Osram advertised the Z77 in 'News for Tx-men' in the RSGB Bulletin (See Z77 Advert). According to the advert the valve 'can be used with success as a power amplifier or frequency multiplier in the early stages of radio transmitters', and in fact you can find this valve (and its equivalents) in these roles in numerous amateur transmitters of the 1950s and 1960s.

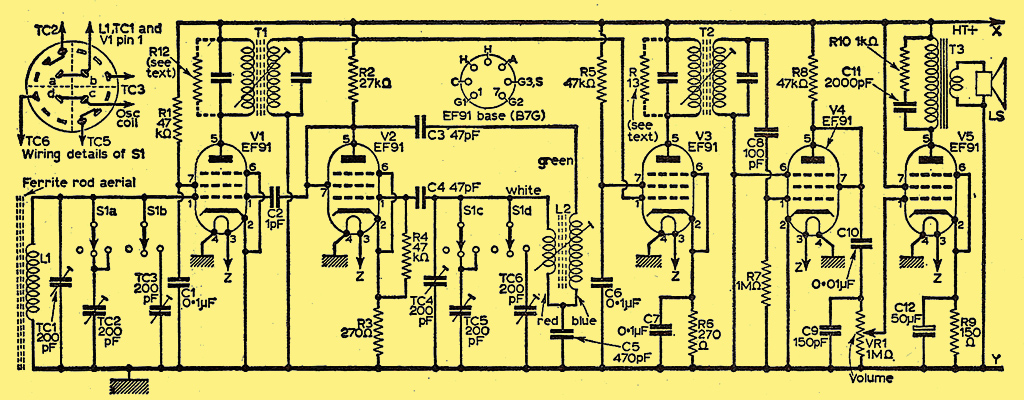

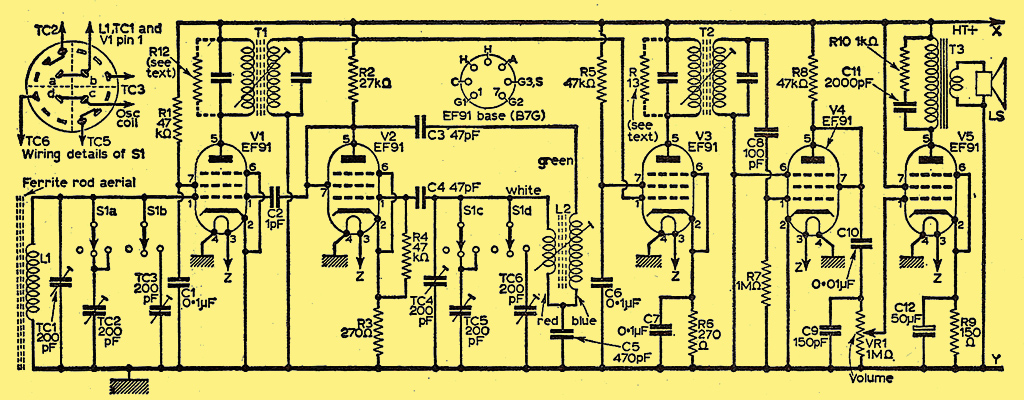

You can find many articles in the amateur press using the EF91. For example, Practical Wireless published 'The Versatile EF91' by K V R Bowerman in its February 1964 issue. This article described an EF91 4-valve push-pull audio amplifier and a 5-valve switched MW/LW superhet.

A 5-valve switched MW/LW superhet using ef91s. Click image to enlarge.

Both designs used 100% EF91 line-ups. A couple of years ago I managed to buy an example of this home-built superhet on eBay. A photo of its EF91 line-up is shown below. Behind the two valves at the left of the chassis are the Denco aerial and oscillator coils in their screening cans.

The EF91-based 5-valve switched MW/LW superhet I bought on eBay. Hopefully you can see the blue tint of the Mullard EF91s used. Behind the two valves at the left of the chassis are the Denco aerial and oscillator coils in their screening cans. See also the Fane elliptical loudspeaker: after disappearing between 1989 and 2007 Fane was resurrected and now manufactures in Wakefield, not too far away from the original location in Batley, Yorks.

The cheapest I could see the EF91 being sold for in this 1964 issue of Practical Wireless was 2/9d: the cover price of the magazine that month was 2/-, so hopefully you can get a feel for how expensive or cheap the valve really was. Interestingly the cheapest valve in this issue was the EF50, at 1/6d, so if you could stand to use 'old technology' the EF50 was definitely a bargain!

Another all-EF91 project was 'A TRF Communications Receiver' by R H Wright in the September/October 1959 issue of Practical Wireless, as was 'A Simple 3-Valver' by T M Bush in the December 1962 issue. In Practical Wireless for July 1961 'An Amateur Communications Receiver' by P Hayes was published, which used EF91s for the RF amplifier, mixer and oscillator stages, and the three IF amplifiers.

The British Valve Association

The number of identical valves to the EF91 (and many other valves of course) is partly because of the existence of the British Valve Association (BVA), established in 1926 and which continued into the 1950s. This was a cartel of the seven major valve manufacturers in the UK that was (supposedly) chartered to protect the interests of the UK valve industry from foreign competition. This organisation dictated (amongst other things), the price of valves; how and where they were to be sold and what discounts could be applied; and of course how they were numbered, though as we know many manufacturers used their own historical numbering systems. US types, such as the 6AM6, manufactured in the UK by companies such as Brimar, sold in the UK at the same price as their UK counterparts because of the BVA's rules, whereas in the US they sold for something like half this price. Of course although this protects the valve manufacturers' profits it can also have a negative effect on equipment manufacturers, but remember that in many cases the valve manufacturers and the radio manufacturers were divisions of the same company. This type of price fixing is generally frowned upon and is unlawful today.

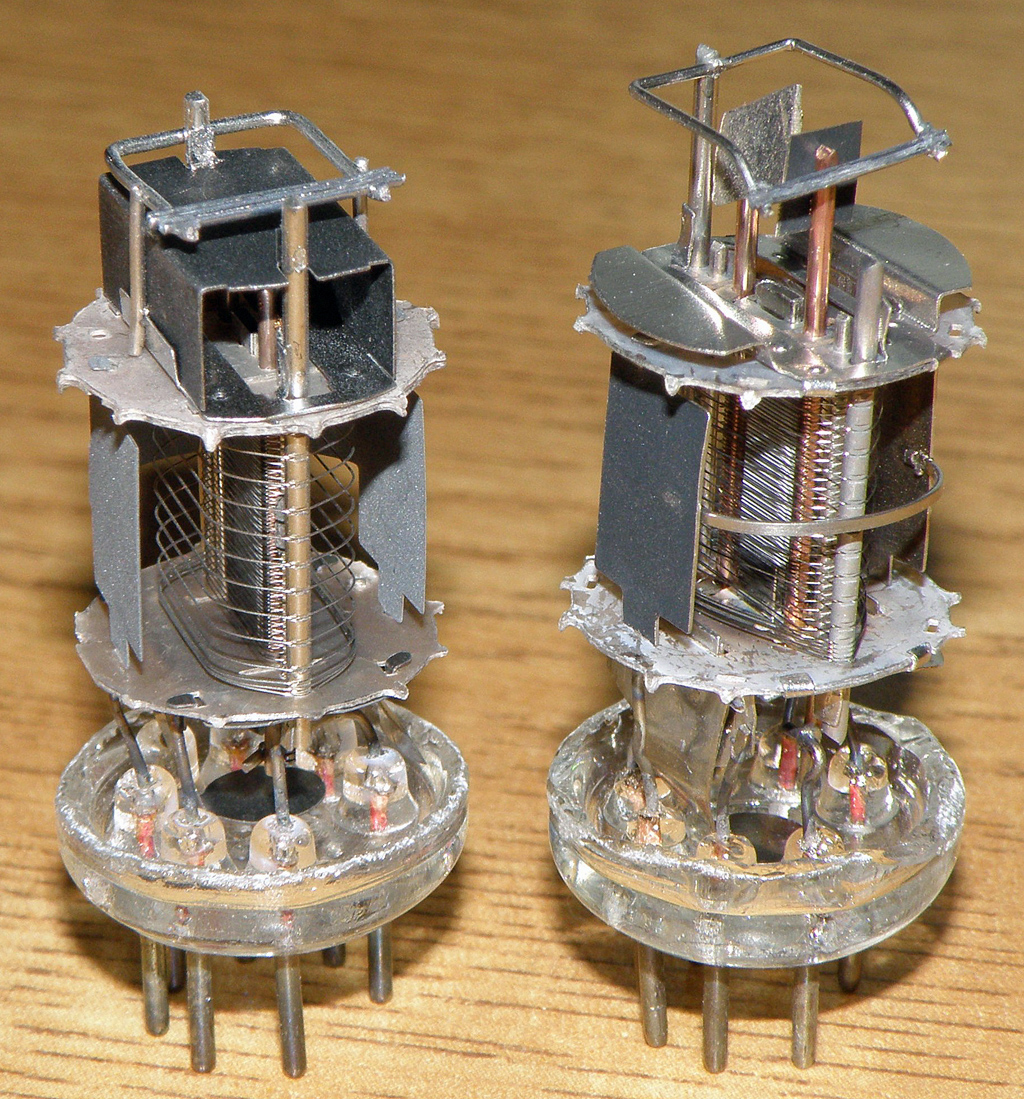

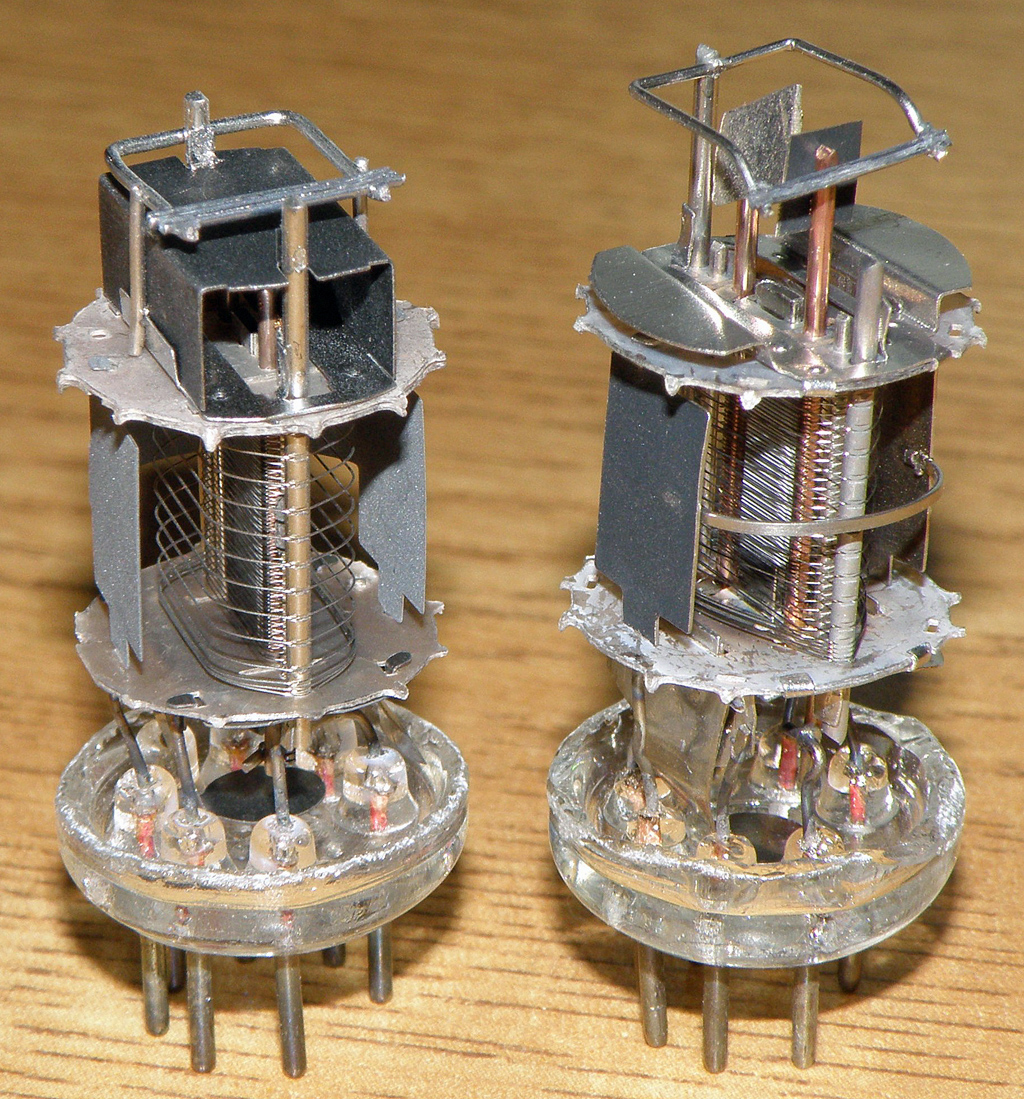

Construction of an M-OV Z77 (left) and a Mullard EF91 (right). You can see that they are not mechanically identical, but were electrically close enough to be called equivalents. The anode consists of the two vertical plates which are strapped together 'round the back'.

The BVA encouraged the exchange of patents and specification information amongst its members so that second (and third, and fourth, etc.) sources were produced for many popular valves. (See Valve Standardisation.) This gave radio manufacturers the confidence that a particular valve wouldn't suddenly disappear, say for example because of a fire at a particular factory. The valves so produced weren't necessarily mechanically identical to each other (as can be seen above, showing the internal construction of an MWT Z77 and a Mullard EF91) but were electrically close enough to be called equivalents. How close is 'close enough' is a good question. Below we have the specifications of Ediswan and Mullard EF91s, they show that the transconductance (gm) parameter is slightly different, but 'close enough' to make no significant difference in most applications.

| Vh | Ah | Va | Vs | Vg | mAa | mAs | ra | gm |  | 6.3 | 0.3 | 250 | 250 | -2 | 10 | 2.5 | 1M | 7.6 |

Mullard EF91 data.

| Vh | Ah | Va | Vs | Vg | mAa | mAs | ra | gm |  | 6.3 | 6.3 | 0.3 | 250 | 250 | -2 | 10 | 2.5 | 0.9M | 7.5 |

Ediswan Mazda 6f12 data.

The specification of the Brimar 6AM6 (from 1952) can be seen by following the link to the exhibit, note that the sheet indicates that the valve was 'previously coded 8D3', so it looks like the re-branding away from the 8D3 was complete by this date. It may be that 8D3 was regarded as being an 'old-fashioned' code whereas 6AM6 projected a more modern image.

There is clearly a 'story to be told' about the BVA, beyond the scope of this article. The Set Makers 1002, London: The British Radio & Electronic Equipment Manufacturers' Association. by Keith Geddes and Gordon Bussey, published by BREMA in 1991 contains much useful information about the organisation and how it operated.

All manufactures published their own lists of 'equivalents' between their own valves and those of other manufacturers, including American types, so cross-referencing was relatively easy. Amateur organisations, such as the RSGB, also produced booklets showing the commercial equivalents of CV valves, especially just after the war when surplus CV valves were being released into the amateur market in vast numbers, and were easier to lay your hands on than commercial valves.

Above is a small section of the 1947 RSGB booklet - Service Valve Equivalents1065. This document comes up for sale on eBay quite often). As you can see at the time the CV138 was stated to be equivalent to the STC 8D3 and the Mazda V888 (which was probably a development code for the valve that actually appeared as the 6F12), but no mention of the EF91 at this date. It's interesting that the CV138 was available so early in the life of its commercial equivalents: maybe the valve was used in service equipment before its use in commercial radios and TVs? Beware of using too much of the information in the booklet: there are several inaccuracies on just this first page. To be fair on the compilers it must have been difficult to obtain relevant and accurate information so soon after the war. (The museum equivalents list has been compiled from many sources since the year 2000).

The CV2001

An interesting variant on the EF91 was the CV2001, which has flying leads apparently for soldering directly into equipment. I was very lucky to come across a CV2001 at the BVWS meeting in Wootton Bassett about a year ago. If you look closely at the arrangement the valve looks like a 'normal' EF91 (presumably it's actually a CV138 or similar service-spec valve, or even a CV4014), plugged into a socket which has flying leads attached for soldering into equipment. The valve is labelled CV2001, which presumably is the designation of the combination of valve plus socket. It's still a mystery exactly what this valve was used for and I have no 'definite sightings' so far. If you've seen one used in a piece of equipment please let me know.

The valve in the photo above has 'VF' printed below the ? (up arrow) symbol (just 'round the corner' of the photo and out of view), indicating the date of manufacture of June 1964, so this is well into the transistor era. As you can see, below the CV2001 code is the marking 'KB/AD': 'KB' indicates that the valve was made to specification K1001 or K1006; and 'AD' shows that this valve was manufactured at Thorn-AEI (Brimar) in Rochester.

Brimar and Brimarizing

In the late 1940s Brimar (the valve manufacturing division of STC) launched a campaign to 'Brimarize' the consumers of valves, that is to get as many as possible to design in Brimar valves, or to switch to Brimar if they were using other manufacturers' valves. The above advert featured in the RSGB Bulletin in September 1953 and the same design appeared in Wireless World August, 1953, both emphasise the improved quality you got with a Brimar 6AM6/8D3, rather than with an EF91, etc.

In the 1953 Brimar Radio Valve and Teletube Manual 4053 there is a 'Brimarize' section written especially for the Service Engineer, to help him to select a satisfactory replacement valve for one that is obsolete or unobtainable'. There is also a section on 'Valve Ratings' with particularly useful recommendations on the voltage that should be applied to filaments (on directly heated valves) and heaters (on indirectly heated valves). It advised that nominally 1.4V filaments could be operated in the range 1.25V-1.4V, and heaters (presumably of nominally 4V, 5V, 6.3V and 12.6V) could be operated at 17% of the nominal value. This is really useful information, which I've searched for, but have never been able to find, on valve data sheets.

Valve Making

The National Valve Museum includes much valve data, and also films of valve making in Osram in 1930 (complete with a rather French-sounding accordion sound track), and EF80 manufacturing at Mullard's famous Blackburn works and additionally an article on EF80 construction - the EF80 superseded the EF91. It's also worth searching on YouTube for valve films. It's fascinating how many sub-factories were involved in the process to produce all the bits and pieces, and sub-assemblies before the valve was assembled and evacuated.

In the early 1950s several Brimar adverts featured some of the machines used to make their valves. Illustrated above are stem making and grid winding machines. Note the comment: 'We regret that for the present our supplies of these machines must be for export only'. I wonder if this is a government-imposed rule to encourage exports? (Post war finances in the near bankrupt UK made export the number one priority command for all manufacturing industry - ed.). You would think that in the long run the spread of advanced valve-making technology to the rest of the world would be to the detriment of the UK-based industry.

Special Quality Valves

It's worth looking at Mullard's rather short film 'Special Quality Valves' made in 1956, on the 2010 BVWS DVD, if you have it handy and now also on the National Valve Museum's DVD set. We tend to think today that the heater is the weak point of any valve, and quite rightly we are careful with the heater voltage we apply. The film shows some of the other breakdown mechanisms, such as rapid mica wear and the fracture of welds, of standard valves when they are subjected to mechanical vibration found typically in many industrial and military environments.

Brimar adopted the rather vague term 'Trustworthy Valves' when referring to their high reliability or ruggedised (as we would refer to them today) versions of the EF91, and many other valves of course. The Brimar advert shows how the 6064 is described as a Trustworthy version of the 8D3. The 6064 was definitely a re-design of the 8D3 and Brimar explained the design of the Trustworthy range in a Wireless World article in March 1952. Below is a diagram from the article showing the way the structure of a valve could be modified to make the valve more reliable. The article makes it clear that this does not represent any particular valve type but is a general illustration of the technique.

As far as I can tell the CV138 was not the service equivalent of a ruggedised valve, and so I though it worthwhile to open one up and take a look at the structure inside. Since I had a GEC CV4014 I also opened this up and as you can see from Figure 16 this has a modified structure and so I presume it is based on the 6064, rather than the EF91. The Mullard CV138 looks very much like the EF91. This makes me wonder how reliable the CV138 was: can anyone out there comment on whether the CV138 was reliable under military conditions?

M-OV CV4014 (left) and Mullard CV138 (right). (click image to enlarge). Although you can't see it here the anode of the CV4014/6064 was pressed from a single piece of metal and so the potential weakness of the welded joints on the strap between the two anode plates in the EF91 and CV138 was eliminated. The getter is also now supported at four points, rather than two. The manufacturer's code 'Z' for this example showed it was made in the M-OV Hammersmith factory.

Service Valve Reliability

In Wireless World for March, 1951 the question 'How Reliable is a Radio Valve?' was posed. The answer was a qualified 'not very', as concluded at a recent IEE meeting. One speaker reported that 'the valve was quite reliable enough for present day entertainment purposes, hardly adequate for serious industrial use, and quite inadequate for aircraft equipment'. C S Cockerell (was this the self-same inventor of the Hovercraft?) had tested a large number of valves, including the CV138, and had found that out of 18,700 samples, 697 had either developed faults during a 50-hour test on stationary racks or had found to be faulty when drawn from stores.

This leads to me to the conclusion that the CV138 was simply the EF91 (or its aliases) procured under a common code, and not tested or selected for robustness. I presume since the CV4014 was the service version of the ruggedised 6064 or the M8083, then it should have been considerably more reliable in service duty. (evidence in the data agrees with this conclusion - ed) It was used for example in the Murphy B40 naval receiver.

Prices Then and Now

As discussed earlier the BVA regulated valve prices for a long period, and certainly during the 'design in' life of the EF91 and its equivalents. The table above shows a few lines from a page of Mullard's Comprehensive Valve Price List with Mullard Equivalents, Third Edition, issued in November, 1952. The list shows the Mullard EF91 being a direct equivalent to the Brimar 6AM6, and the Mullard price is 17/6d, which presumably was also the price of the Brimar valve, in the UK at least. Earlier in the price list a table on purchase tax 'payable on valves and television picture tubes on and after 11th April 1951' was shown. In addition to the 17/6d list price for the valve, purchase tax of 7/7d was payable to the government. According to my calculation this represents a tax rate of 43%!

Because the valve is so ubiquitous and was made in vast numbers it is still easy to find and cheap to buy. Be warned: I've seen EF91s being sold on eBay for up to £20 each - don't be mislead (for most projects at least) by claims of high quality specimens, matched pairs, 'rare' versions with special markings, and so on. This valve is not in the same class as those used in 'classic' Hi-Fi and guitar amplifiers. You'll find it at radio rallies, vintage radio meetings, and on the www, and you should be paying about £1-£2 per tested, boxed valve. You'll always find a few EF91s sloshing around at the bottom of a box of old valves: try these if you wish, but don't pay much more than 50p each for them. I'm sure the TV restorers amongst you will have bucket loads of EF91s.

The EF50 and EF80

Although in theory the EF50's useful design in life probably ended at the end of the war, as late as September 1965 Practical Wireless published 'The Versatile EF50' by J B Wilmot. This article is a very useful reference for valve users, showing the pentode used in various detector configurations (with and without reaction); RF and IF amplifiers; audio pre-amplifier and output stages; and as a phase inverter.

The early 1950s was a time of rapid development in valves even though the basic technology was by now many decades old. The EF91 was probably the valve of choice in TVs for only 3 years or so before Mullard started to 'push' its replacement, the EF80. See Mullard's September 1950 view on why the EF80 was now the valve to design into new TV sets, thereby implying that the EF91 was obsolete in that application. A set of component parts and sub-assemblies for the EF80 are shown in 'The Making of the EF80'.

Perhaps as a way of extending the life of the EF91, in Wireless World March, 1950 Mullard featured the EF91 in an advert 'An electronic timer for long time delays using the EF91' - rather remote from its original intended application.

Conclusions

If any valve can claim to be 'the valve that won the peace' then I think the EF91, and its many equivalents and derivatives, must be close to the top of the list. Its sheer number of commercial, industrial and service aliases is evidence that the valve was extremely useful, at first as a high frequency amplifier in post-war TV sets and then more generally where a robust general purpose pentode was needed.

Because EF91s and equivalents are still easy and cheap to get hold of I didn't feel too guilty about 'letting the vacuum out' of a few examples in the interests of science to reveal the internal structures. This made it easy to see the differences between various manufacturers' commercial, ruggedised / industrial (or by the rather vague term 'Trustworthy' - as Brimar insisted on calling them), and service versions of what we today tend simply to call the EF91. I think this helps us understand the way in which valves were manufactured to different specification levels for different applications.

The subject led me to briefly cover some aspects of valve manufacturing and reliability. The internet has given us access to some films of valve manufacturing and a search on YouTube is always worthwhile. The influence on valve sourcing and pricing of the BVA was briefly covered, and I'm sure there's much more to be investigated into how and why this organisation operated in post-war Britain.

This article was originally published in Radio Bygones Magazine and is reproduced by kind permission of the editor.

References

- 'Radio Valves and Tubes - 1 Numbering Systems' by Geoff Arnold. Radio Bygones No 9, February/March, 1991.

- 'Radio Valves and Tubes - 2 UK & US Military Equivalents, pre-1944' by Geoff Arnold. Radio Bygones No 10, April/May, 1991.

- 'Radio Valves and Tubes - 4 Further Data' by Geoff Arnold. Radio Bygones No 14, Christmas 1991.

- 'Valve Coding Systems' by J Alexander. Practical Wireless February, 1960.

- 'Valve Codes What do they Mean?' by Alan Guy. Radio Constructor July, 1964.

- A searchable index of comprehensive valve data can be found: here and at Duncan Amps

- More information on the British Valve Association can be found at: Wikipedia

- The National Valve Museum is a valuable source of valve history and data, including many high quality photos of the valves featured.

- A searchable list of CV valve codes and a full list of CV valve manufacturers' codes can be found at the Virtual Valve Museum.

- Details of the Brimar factory codes.

- Mullard/Philips valves carry a code showing type; manufacturer or country of origin; year, month and week of manufacture; and change symbol. A comprehensive explanation of these codes can be found here.

- A fascinating history of valves can be found in 70 Years of Radio Tubes and Valves by John W Stokes. Published by The Vestal Press Ltd, New York in 1982.

- Radio Valve and Transistor Data by A M Ball is a useful short-form of valve data. Various editions, published by Iliffe.

- All valve period ARRL Handbooks have a useful valve reference data section at the back.

- There are many editions of the Mullard Technical Handbook around which contain useful valve data.

|